From Worn to Reborn: The Power of 3D Scanning in Industrial Maintenance, Repair and Overhaul (MRO)

Industrial operators across energy, mining, aerospace, automotive, and heavy machinery sectors often face critical downtime when legacy or custom equipment needs maintenance and/or repair. Traditional reproduction methods—manual measurements, 2D drawings, or trial-and-error machining—can be quite slow, error-prone, and costly.

3D scanning and reverse engineering present a digital-first alternative. By capturing complex geometries with metrology-grade accuracy, engineers can recreate, optimize, and validate industrial parts in days rather than months. This article explores the features, advantages, and benefits of this technology, while highlighting its value and return on investment (ROI) for rebuild and remanufacture applications.

Challenges with Traditional Methods

Long Lead Times: OEM replacement parts may require months for procurement, particularly for obsolete parts where tooling no longer exists. Critical equipment can sit idle during this period leading to costly disruption and downtime.

Incomplete Documentation: Many legacy systems lack CAD models or up-to-date drawings. Reproducing parts relies heavily on skilled labor and manual interpretation.

Complex Geometries: Impellers, turbine blades, and freeform castings are difficult to reproduce accurately using tactile measurement or manual digitization.

Fit and Tolerance Issues: Even small dimensional inaccuracies can cause vibration, premature wear, or outright failure, leading to costly rework and further potential downtime.

High Production Costs: Manual reproduction often requires multiple iterations, each consuming costly time, material and leading to added delays.

These challenges create operational inefficiencies, extending downtime and increasing risk.

Features of 3D Scanning and Reverse Engineering

High-Resolution Data Capture: Handheld Laser and structured-light scanners deliver sub-millimeter accuracy, suitable for intricate, worn, or delicate parts.

Non-Contact Measurement: Reduces the risk of damaging fragile or eroded components.

Field-Portability: Modern scanners can be deployed on the shop floor or in the field, minimizing disassembly and transport delays.

Flexible Output Options: Data can drive CNC machining, casting, or additive manufacturing (metal or polymer).

Rapid Scan-to-CAD Workflows: Scanned meshes are processed into editable CAD surfaces and solids compatible with major CAD/CAM software, such as inventor, Solidworks and Fusion360. Software such as Geomagic DesignX and QuickSurface can great enhance and speed up this process.

Deviation Analysis: Comparison between scan data and CAD models can ensure design intent and tolerance compliance before manufacture.

Advantages and Benefits

Reduced Downtime: Parts can be scanned and reverse engineered digitally in hours to days, compared to days to week using traditional measurement methods.

Design-Intent Recovery: Reverse engineering reconstructs functional surfaces, correcting wear or defects before remanufacture.

Quality Assurance: Scan-to-CAD workflows include verification steps, minimizing risk of misfit and reducing rework.

Process Flexibility: Digital models allow manufacturers to select the best production method—CNC machining for robustness, additive manufacturing for complex geometries, or casting for scale.

Documentation and Digital Twin Creation: Legacy parts can be archived digitally, supporting future reproduction and integration with Industry 4.0 systems.

Non-Destructive and Scalable: Components from small precision turbine blades to large pump impellers can be captured with the same core process.

Value and Return on Investment

The adoption of 3D scanning and reverse engineering yields measurable returns in multiple dimensions:

Time Savings: 3D Scanning provides a significantly faster means of capturing measurements compared to manual methods.

Cost Avoidance: Eliminating prolonged downtime can save millions in industries where each hour of lost production carries significant financial impact.

Resource Efficiency: Reduces reliance on scarce manual measurement expertise; digital workflows lower labor intensity and rework rates.

Asset Life Extension: Reverse engineering supports remanufacture of obsolete or unsupported equipment, extending the useful life of capital assets.

Innovation Opportunities: Digital models allow for optimization—improving efficiency, reducing material use, or enhancing performance compared to the original part. Design modifications and improvements to the design can be made digitally ahead of fabrication.

Real World Examples

Hydropower Turbine Renewal Design

Source: https://www.3d-scantech.com/hydropower-turbine-renewal-design/

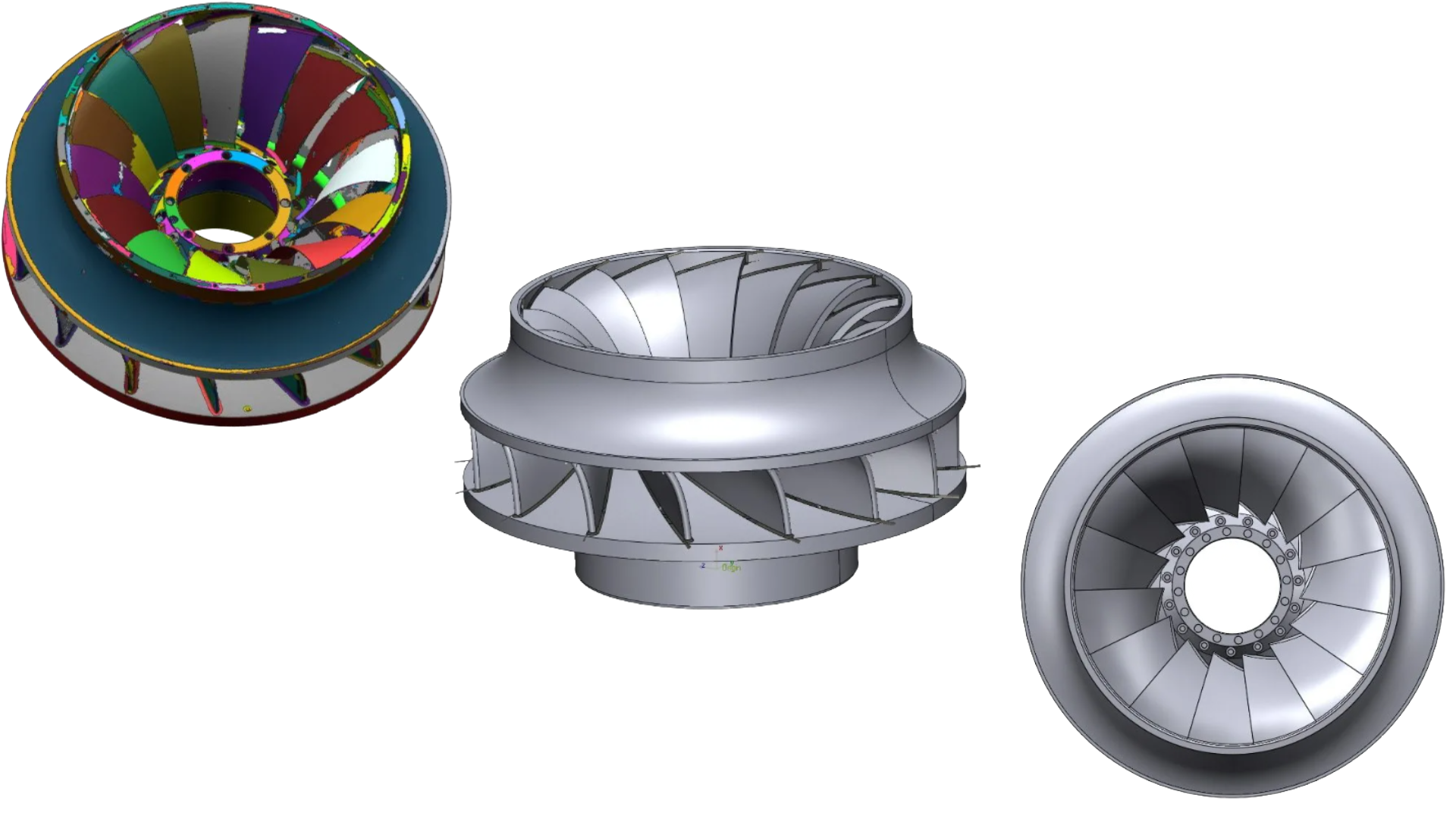

A hydropower facility faced the challenge of modernizing its aging turbine system to improve efficiency and extend its operational life. Traditional approaches to capturing the complex geometry of turbine blades and housings would have required lengthy manual measurement and introduced a high risk of error. The plant needed a fast, accurate, and non-contact method to document the worn structures and generate a reliable digital foundation for redesign.

Using Scanology’s KSCAN-Magic 3D Scanner, engineers captured the large turbine components with metrology-grade accuracy. The scanners blue laser scanning enabled precise, high-speed digitization of freeform surfaces, even under demanding site conditions. This Scan-to-CAD process allowed the team to create a complete digital model of the turbine, identify wear patterns, and support optimized renewal design.

The outcome delivered substantial value: the project reduced downtime, minimized engineering rework, and provided a validated digital twin of the turbine for ongoing asset management. By enabling accurate redesign and manufacture of turbine parts, the workflow not only restored performance but also safeguarded the long-term efficiency of a critical renewable energy resource.

Designing Custom Mining Solutions

Source: https://www.artec3d.com/cases/titan-engineered-solutions

Titan Engineered Solutions specializes in designing and installing custom mining equipment such as safety platforms, flooring, and piping systems. Traditionally, their engineers faced long journeys to remote sites, where they spent hours capturing manual measurements—an approach prone to errors, incomplete data, and costly repeat visits. With many mines relying on aging or obsolete infrastructure, even minor measurement mistakes could cause severe downtime and reduce profitability.

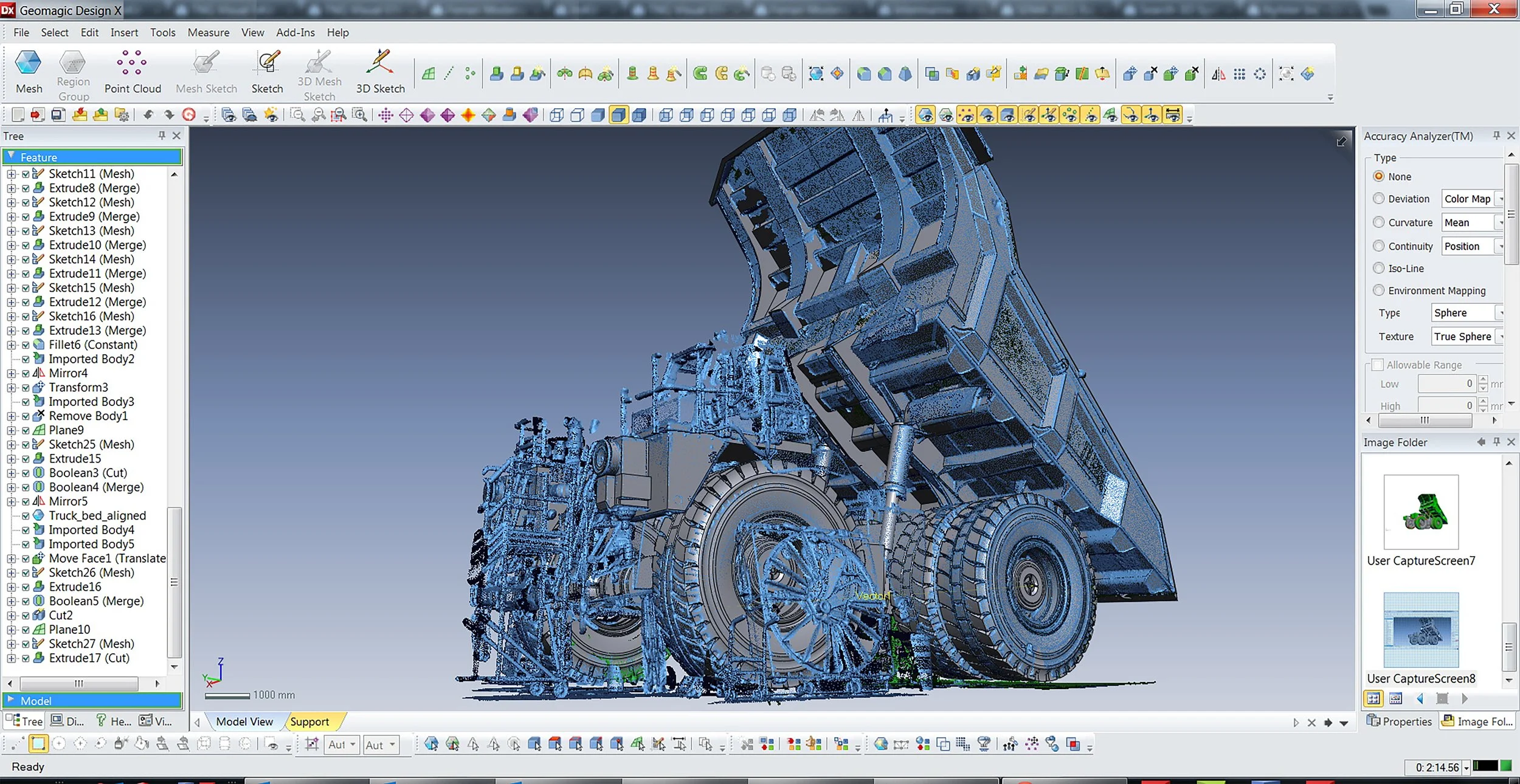

To overcome these challenges, Titan adopted Artec Leo and Artec Ray 3D scanners, along with Artec Studio and Geomagic Design X software. This combination enabled rapid, accurate digitization of both small details and large mine environments. The new workflow supported “virtual test fitting,” allowing engineers to ensure that equipment designs would integrate seamlessly into existing infrastructure before fabrication and shipment.

The value of this transformation has been significant: measurement lead times were cut by two-thirds, design errors drastically reduced, and downtime minimized. By replacing manual methods with agile 3D scanning and reverse engineering, Titan not only improved accuracy and efficiency but also delivered faster, more reliable solutions to clients operating in demanding mining environments.

Conclusion

3D scanning and reverse engineering provide a transformative approach to industrial part rebuild and remanufacture. By overcoming the limitations of traditional methods, these technologies enable rapid reproduction, precise quality control, and flexible production pathways. The result is a compelling value, driven by reduced downtime, lower costs, and extended asset lifecycles.

Organizations investing in this digital workflow not only safeguard operations but also lay the foundation for future-ready manufacturing capabilities, including predictive maintenance and on-demand digital part libraries.