We engineer fittings that seal leaks!

Proudly serving -> Industrial Service Companies, Oil and Gas Facilities, Power Generation Facilities, Nuclear Plants

If you have:

Thinning pipe

Cracked piping

Pinholes

Corroded piping

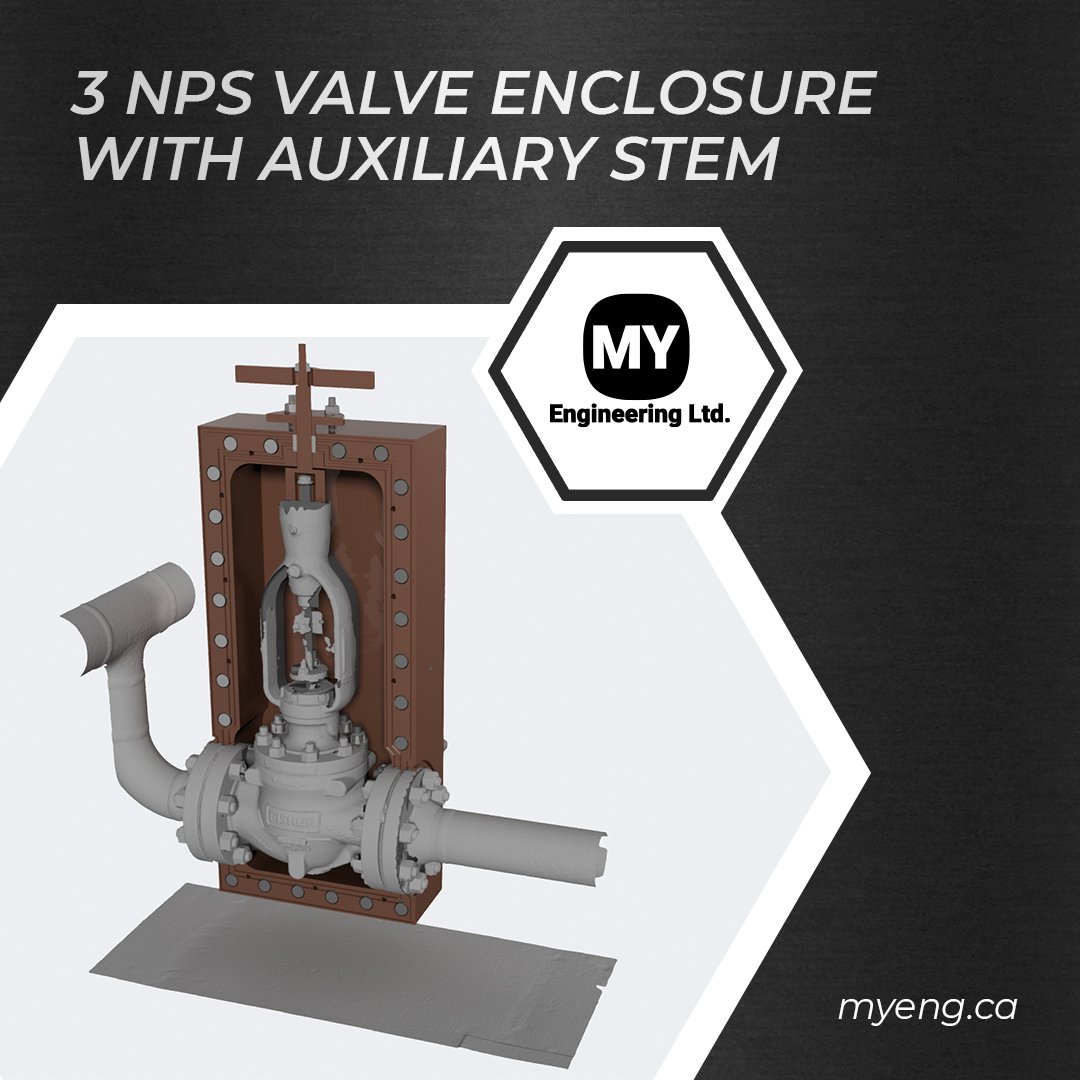

Leaking valves

Leaking flanges

Exchanger gasket leaks

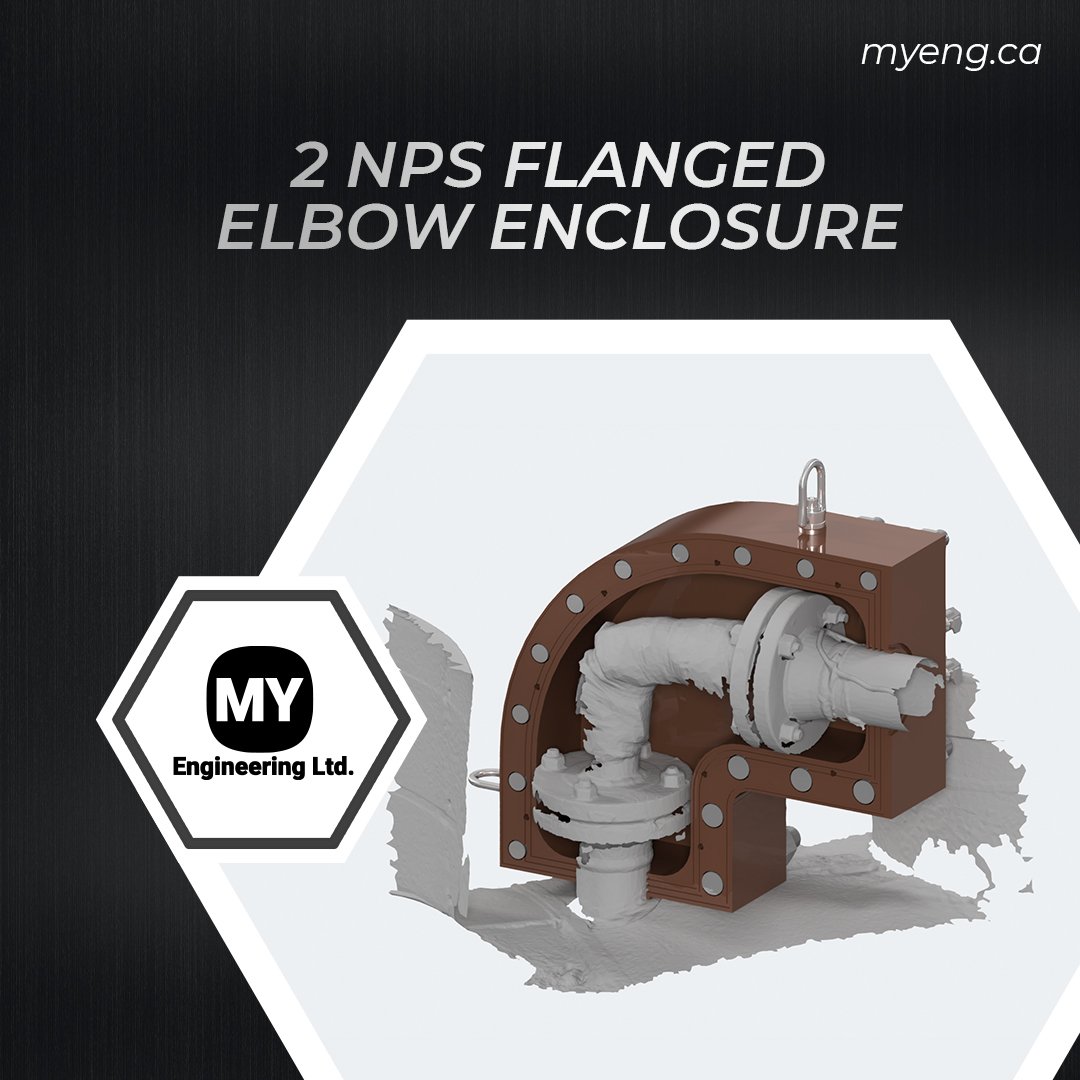

Elbow leaks

Weld porosity issues

API tank corrosion

or another pressure equipment issue

We have a solution!

We design…

Custom designs

Leak Repair Fitting Catalogs

Strongbacks

Flange Restraints

Designs from 3D scan data

All designs by My Engineering are ASME compliant

We have:

Completed hundreds of designs from 3D scan data

Trained dozens of technicians in 3D scanning

Saved refineries/power generating facilities millions of dollars with our repairs

Developed 3D scanning programs for leak repair companies

Developed quality programs, process maps, procedures, policies, and checklists for using 3D scanners for leak repair

The leak repair process should be simple, safe, and fast

Involving My Engineering keeps it that way

What separates My Engineering from the competition is that we are involved in all steps of the leak repair process. We actively work with our customers and vendors to achieve the final goal of safely, quickly, and effectively repairing defects in piping.

Our clients involve us at the conceptualization phase so we can brainstorm potential solutions, identify safety risks such as the need for strongbacks (piping restraints | flange restraints | ect), and assess the root cause of the issue and how it that will affect the enclosure design.

A few other things we do to ensure the leak repair project is successful is:

We send early conceptual design concepts to our clients to gather feedback and perspective to ensure that no time is wasted in pursuing a solution that will not work for an unforeseen reason.

We also assist in selecting the appropriate sealing mechanism, and sealing materials to ensure that the chance of success is maximized.

We work closely with manufacturing to ensure the design can be manufactured in the quickest amount of time, using available materials, and for the lowest cost.

Interested in learning more?

Did you know?

Did you know there are many names for leak repair enclosures? Some common examples are below

Leak repair enclosure

Coffin

Engineered leak containment device (ELCD)

Engineered pressure enclosure (EPE)

Box

Sleeve

Leak repair fitting

See what our clients have to say…

What else do you offer?

Along with custom leak repair enclosure design, we offer:

Sealant injector design / injection valve design

Sealant injection gun design

Injection ring design

Cap nut design

High pressure packing gland design

Injector extension design

Angle nut design

Curious about our work product? Here is a sample design… (Click to expand)

Get the best… everytime!

All designs from My Engineering include:

Machining notes

Stamping notes

Enclosure weight

Void volume

Sealant volume

Injection pressure

Customer / end user specific requirements

Want to learn more?

Before you go, you may be interested to know that…

We are world leaders in designing online repairs from 3D scan data.