An Automated, Full-Surface Flange Inspection Tool for Field Use

Deliver defensible, ASME PCC-1-aligned go / no-go decisions while cutting flange inspection time by up to 90%.

Designed for field teams responsible for flange integrity, including:

Reliability Engineers

Turnaround Teams

Inspection Contractors

Quality Managers

Mechanical Engineers

Asset Integrity Engineers

Inspection Supervisors

Revolutionizing Flange Inspections

Flange leaks lead to lost production, unplanned outages, and emissions events. Ensuring flange integrity before equipment is placed into service is critical to reliable and compliant plant operation.

Traditional flange inspection methods—such as dial indicators and contact probes—are accurate but slow, labor-intensive, and difficult to apply consistently in real-world plant environments. Setup time, access limitations, and manual measurements often make full inspection impractical, leaving many flanges unverified.

FlangeVision changes this.

By combining fast, mobile, non-contact 3D scanning with a custom ASME PCC-1–aligned software platform, FlangeVision makes comprehensive flange inspection practical—delivering rapid, repeatable results and standardized reports that support reliability, compliance, and reduced downtime.

Why FlangeVision?

-

Identify out-of-tolerance conditions early and remove uncertainty from joint assembly.

Improve your leak tightness program with fast, and accurate assessment.

-

One operator. No contact. No complex setup.

-

Full circumferential and radial flatness analysis.

Automated measurements for raised faces and overall flange thickness.

-

Clear pass/fail results support consistent acceptance criteria across sites.

-

Standardized reports provide proof of inspection long after the job is complete.

-

Faster decisions on the condition of flange surfaces minimizes equipment cost, eliminates the need for un-necessary machining, and allows you to inspect all your equipment within the expected shutdown schedule.

Simply: Scan. Analyze. Report.

Scan

Advances in 3D scanning technology have made comprehensive flange inspection practical for the first time. Today’s handheld scanners capture full flange geometry in minutes—wirelessly, without physical contact, and with sub-thousandth accuracy.

Integrated scale bar referencing ensures accuracy is maintained across large diameters, allowing anything from small piping flanges to large exchanger faces and vessel flanges to be scanned quickly and without distortion.

Unlike traditional inspection methods that require extensive setup, repositioning, or multiple technicians, FlangeVision’s scanning process is fast and flexible. A single operator can scan large flanges and exchangers in minutes—without custom fixtures, heavy equipment, or cranes—dramatically reducing inspection time and site complexity.

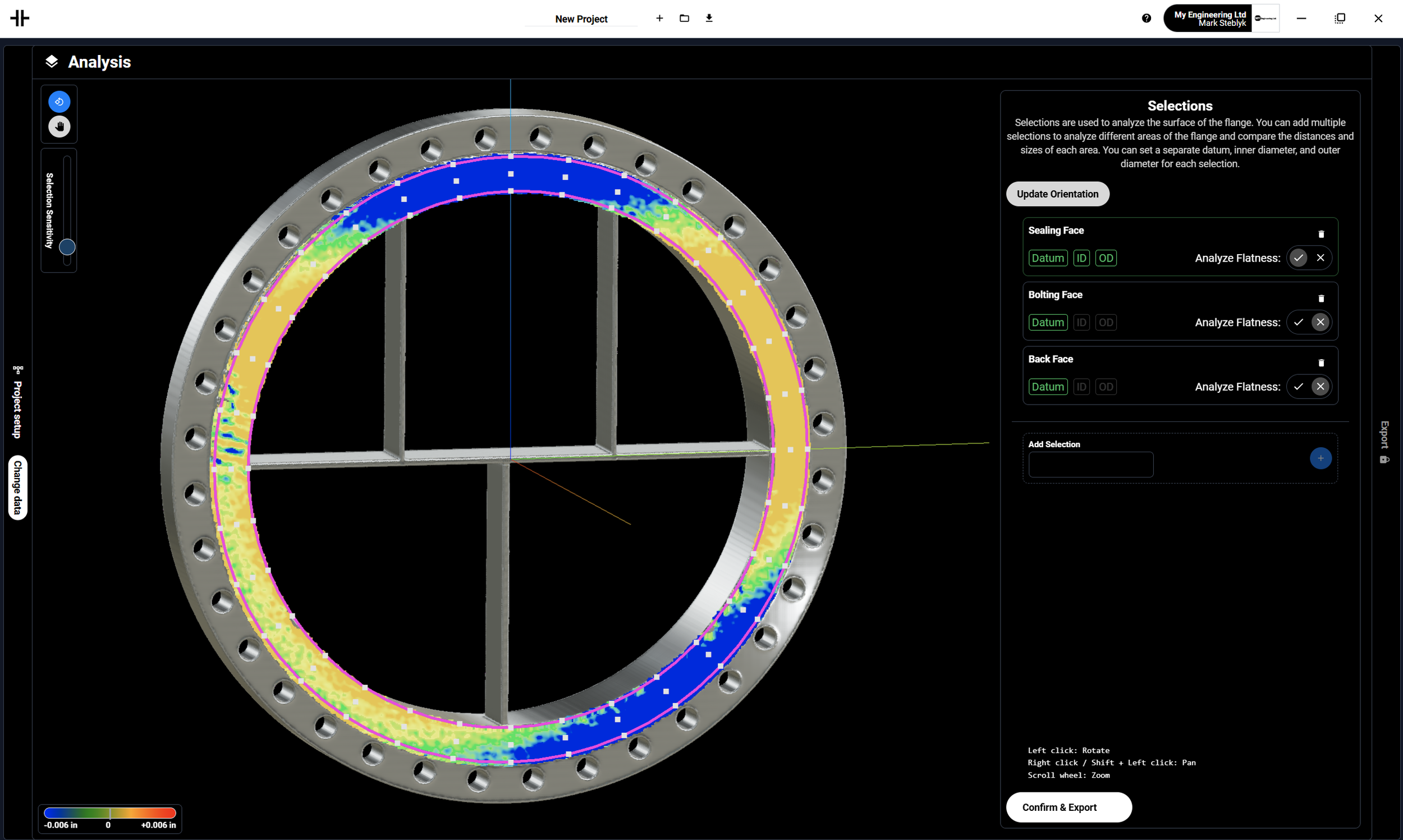

Analyze

FlangeVision analyzes the complete flange surface to determine its true shape. This includes both circumferential flatness—how flat the flange is as you move around its circumference—and radial flatness (often referred to as runout)—how flat the surface is from the inside diameter to the outside diameter.

By evaluating both measurements together, FlangeVision provides a complete and accurate picture of flange geometry, rather than relying on isolated point measurements.

The analysis automatically evaluates raised face and bolting face thicknesses and highlights out-of-tolerance conditions instantly using clear visual indicators aligned with ASME PCC-1 acceptance criteria— allowing technicians and engineers to quickly determine go / no-go conditions.

Technicians can also record flange identification, customer details, and surface condition notes to ensure each inspection is fully documented and traceable.

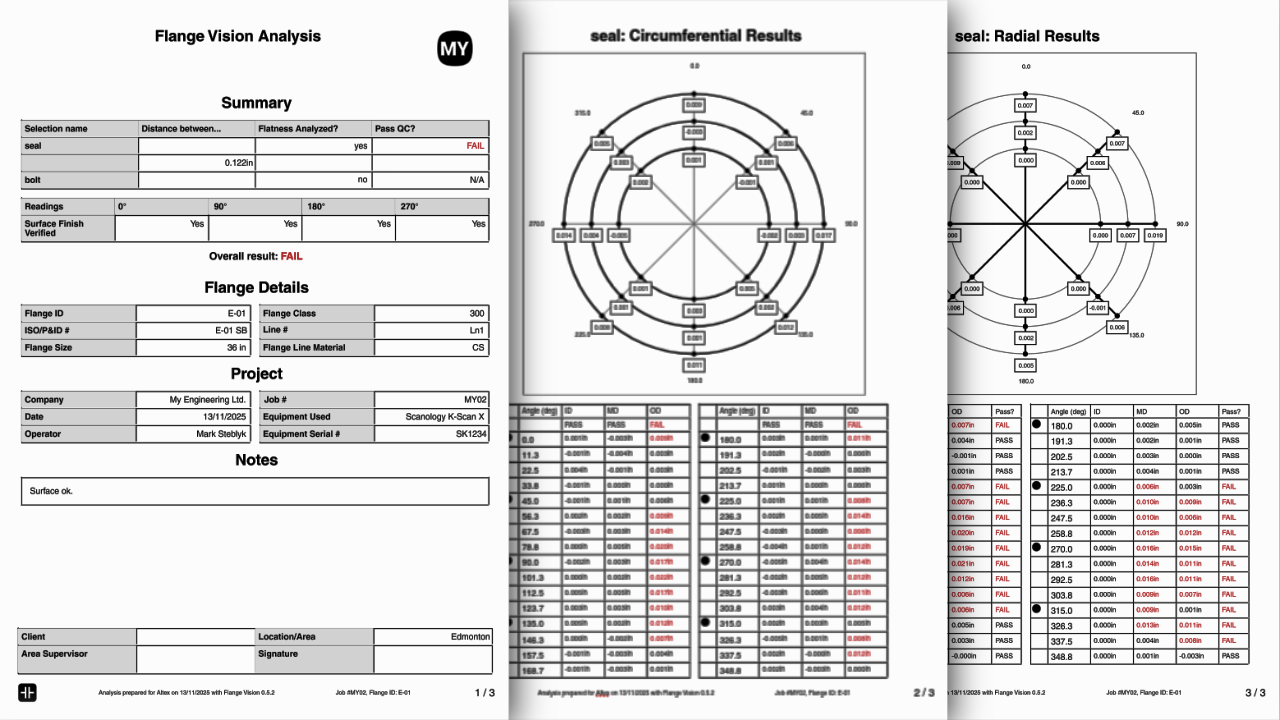

Report

FlangeVision generates detailed, standardized inspection reports instantly—ensuring consistency across inspections, technicians, and sites. Reports can be personalized with your company branding, personnel, and equipment details, making them easy to share, archive, and integrate into existing quality and reliability workflows.

Each report provides full traceability, linking inspection results directly to the specific flange inspected. 3D isometric views allow quick visual confirmation of the flange in the field, while full surface color maps clearly illustrate the flange face profile and any deviations.

All critical analysis results—including circumferential and radial flatness deviations, face thickness measurements, and clear, color-coded pass/fail indicators aligned with ASME PCC-1—are presented in an at-a-glance format to support confident decision-making.

-

Yes. FlangeVision accepts .STL format mesh files which is a common industry format. Note that the accuracy of scanners can vary, and it is recommended to choose a scanner that meets or exceeds the accuracy required to meet PCC-1, or your customers requirements.

-

No. Your Scanned Data, the FlangeVision project file, and the final flange report are saved locally on your computer.

-

FlangeVision is built around metrology-grade measurement principles, not “visual scanning.”

Dial indicators are trusted because they’re familiar, but they also have real limitations including:

Sampling a limited number of points

Results vary with setup, access, and operator technique

The process becomes harder when studs, piping, and exchanger shells get in the way

With 3D scanning, we’re doing something fundamentally different by capturing the entire flange surface rather than a few measurement points. That means you get:

A full 360° dataset.

Consistent circumferential + radial flatness results.

Repeatable measurements without relying on a perfect indicator setup.

FlangeVision reduces uncertainty because it measures more of the surface, faster—and eliminates manual transcription and calculation errors.

-

Yes. Reports can be personalized with your company branding, personnel, and equipment details.

Frequently Asked Questions

Designed for Industry Professionals

Industrial Maintenance & Service Companies – Reduce measurement time from hours to minutes.

Facility Inspection & Maintenance Teams – Speed up inspections while ensuring accuracy and reducing outage time.

A full flange analysis that once took hours can now be completed in minutes. With fast, clear go / no-go feedback, FlangeVision helps reduce outage time, avoid unnecessary machining, and support confident decisions—while digitally documenting flange condition over time.

The speed and clarity of FlangeVision are best demonstrated in the field.

Flange Vision integrates seamlessly with the 3D scanners we sell and support, making it the perfect end-to-end solution for your inspection needs.