Why Crunch Teeth Don’t Work as Strongbacks in Industrial Leak Repair

In the world of industrial leak repair, safety and reliability are non-negotiable. Strong backs—those clamps designed to reinforce and secure Leak Repair Enclosures, play a critical role in ensuring that temporary or permanent solutions hold under pressure, temperature changes, and operational stresses.

Using “crunch teeth” cut into enclosure bores as a substitute for properly engineered strong backs, on the surface, may sound like a convenient solution: simply machine teeth into the bore of the enclosure, tighten it around the pipe, and assume it grips securely. But the engineering theory—and real-world risks—tell a very different story.

Let’s break down why crunch teeth do not qualify as strong backs, and why relying on them can introduce serious hazards into leak repair applications.

How a Friction Ring Actually Works

To understand the flaws in crunch teeth on an enclosure bore, we need to first look at how a friction ring strong back is designed.

A friction ring creates resistance against pipe movement using friction force, which is calculated as:

Friction Force (Ff) = Normal Force (2U) × Coefficient of Friction (Fg)

Normal force comes from the clamping load generated by torquing the grip studs.

Coefficient of friction depends on the materials in contact (pipe vs clamp surface).

When engineers design friction ring strong backs, they deliberately leave a gap between the two clamp halves. This ensures that when studs are tightened, the pipe itself bears the load. That load translates into a positive clamping force directly onto the pipe, which then generates a reliable friction force. This is a proven design principle.

Why Crunch Teeth on an Enclosure Bore Don’t Work the Same Way as a Friction Ring

Crunch teeth machined into an enclosure bore attempt to mimic a friction ring Strongback by “biting” into the pipe surface. But here’s where the theory breaks down:

Enclosures Must Seal Flush

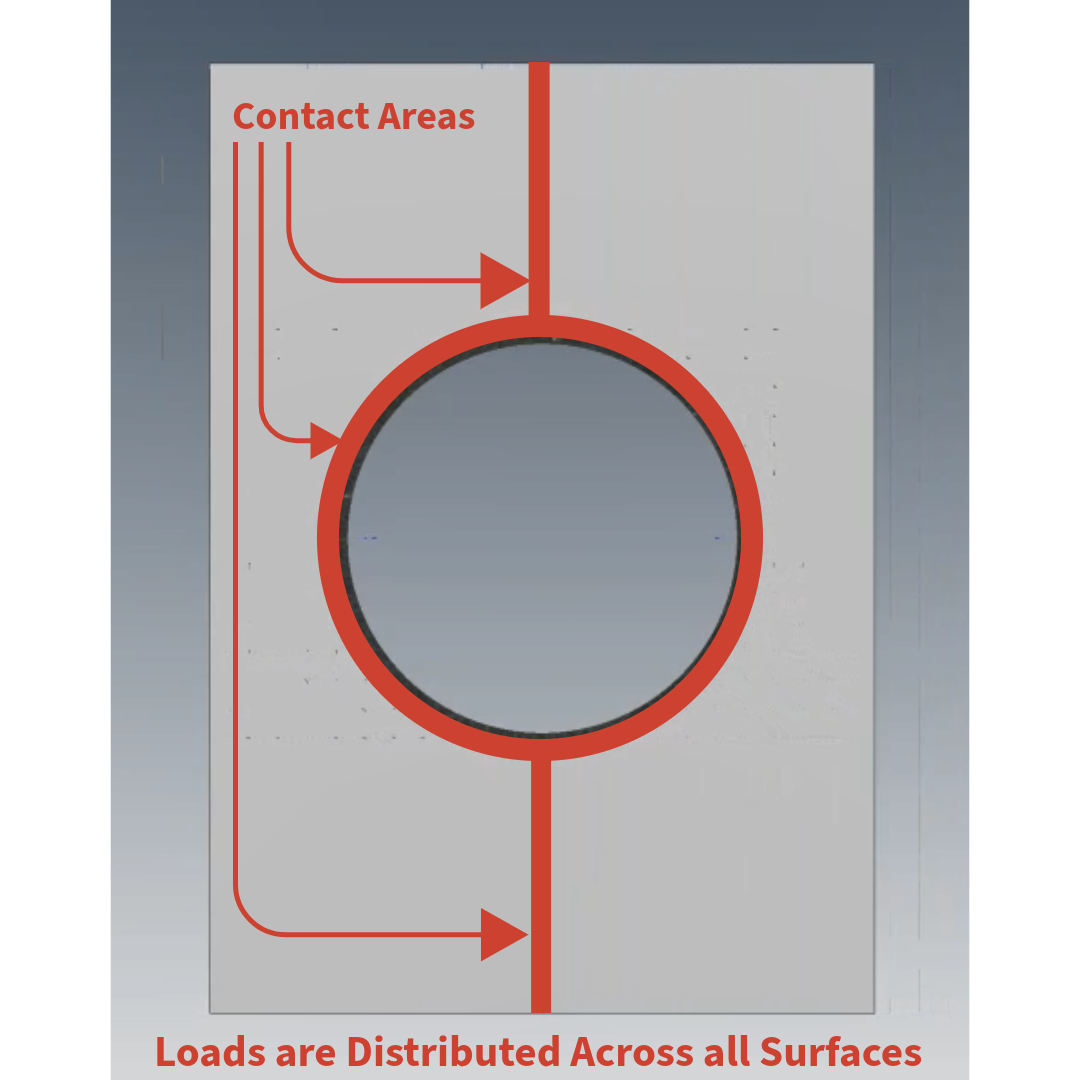

For an enclosure to seal properly against leaks, the two halves must close completely along the split line. Unlike a friction ring, there is no designed gap to preserve clamping force directly onto the pipe.Load Distribution is Diluted

Once the halves come flush, the stud load is distributed across all the enclosure’s mating surfaces—not just the crunch teeth. That means the teeth do not receive a concentrated clamping force, weakening their effectiveness.Loss of Clamping Force with Temperature Cycling

In industrial environments, pipes expand and contract due to temperature fluctuations. If a pipe shrinks, any residual clamping force on crunch teeth can be lost entirely. At that point, the teeth are no longer functioning as friction elements—they are relying purely on shear strength, which is not their intended purpose.Lack of Verified Strength or Standards

Unlike engineered strong backs, there is no accepted engineering method to verify or guarantee the strength of crunch teeth in this application. Testing so far has been limited, inconsistent, and not broad enough to cover different pipe materials, operating pressures, and thermal cycles.

The Safety and Reliability Implications

Strong backs are a safety device. Their role is to prevent catastrophic failures during leak repair, which can otherwise result in uncontrolled releases of hazardous fluids, equipment damage, and risks to personnel.

Using crunch teeth on an enclosure bore introduces several risks:

False sense of security – Operators may assume they have a robust clamp when in reality, the teeth are not maintaining positive friction force.

Failure under load – Without guaranteed clamping, sudden pipe movement or pressure spikes could shear off the teeth, leading to failure.

Inconsistent performance – Different materials, pressures, and temperatures may completely change how the teeth behave, making results unpredictable.

Regulatory and liability issues – Since crunch teeth lack recognized engineering theory and broad testing, using them as safety-critical devices may not meet industry or regulatory standards.

What Engineering Demands

For any component to qualify as a strong back, it must meet at least one of the following conditions:

Be designed according to solid engineering theory – like the friction-based clamping mechanics behind traditional split beam or split ring strong backs.

Be validated by comprehensive testing – across different pipe materials, pressures, and temperatures.

Crunch teeth on an enclosure bore, as they stand today, meet neither condition. While they may seem convenient, without rigorous theory and validation, they cannot be relied upon in safety-critical applications.

Conclusion

The idea of using crunch teeth on enclosure bores as a shortcut for strong backs may sound appealing, but the reality is simple: engineering safety devices cannot be based on convenience.

Until there is comprehensive proof—both theoretical and experimental—that crunch teeth can reliably maintain clamping force and friction across real-world conditions, they should not be considered a substitute for a true strong back.

Strong backs are designed with purpose: to provide predictable, reliable, and safe performance in critical leak repair operations. Anything less is a risk not worth taking.

For further details on Strongbacks, see our article: Strongbacking Explained: A Safety Essential for On-Line Leak Repairs

If you found this information useful and want to learn more about advanced leak repair methods, don’t forget to subscribe to our channel or join our mailing list. We share new insights and tutorials regularly—stay ahead of your maintenance challenges by staying informed.