Strongbacking Explained: A Safety Essential for On-Line Leak Repairs

When it comes to leak repair and piping maintenance, strongbacking is not optional—it’s essential. In this blog, we’ll break down what strongbacking is, why it matters, and how proper implementation can mean the difference between a safe operation and a catastrophic failure.

What Is Strongbacking?

Strongbacking is a structural restraint system designed to prevent pipes, flanges, and enclosures from separating or moving under pressure. It is a layer of protection when cracking, thinning, or other forms of degradation compromise a pipe or joint.

The main types of strongbacking include: Friction Rings, Strongback Bars, and C-Clamps. Other forms of strongbacks exist, but are less common.

Friction Rings – Grip onto pipes using a friction fit to resist separation.

Strongback Bars – Span across or around objects.

C-Clamps – Commonly used on flanges to secure them. Often wire is wrapped around the c-clamps to keep them from falling off the flange.

In simple terms, strongbacking ensures that even if a pipe wall or joint is weakened, the structural integrity is maintained to protect workers and equipment.

Why Strongbacking Matters: Real-World Failures

Let’s look at a couple of real incidents that could have been prevented with proper strongbacking.

Case 1: Pipe Ejection (Health and Safety Executive (HSE), “Leak sealing repair clamps,” HSE.gov.uk.)

The UK’s Health and Safety Executive reported a case where a leak-sealing clamp was installed on a pipe. While the clamp successfully sealed the leak, the pipe beneath had thinned so much that it could no longer handle normal loads.

Without any structural restraint in place, the pipe catastrophically failed—ejecting from the clamp and releasing its hazardous contents.

The root cause was twofold: no proper assessment of the pipe wall thickness was carried out, and no consideration was given to the forces acting on the pipe. Most importantly, no strongback restraint was installed to prevent the pipe from ejecting out of the clamp.

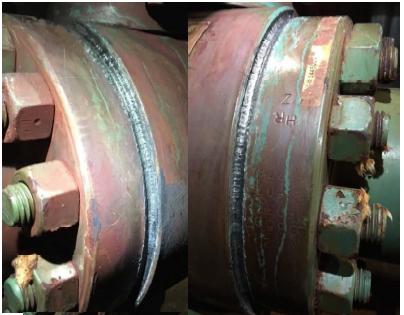

Case 2: Blind Flange Explosion

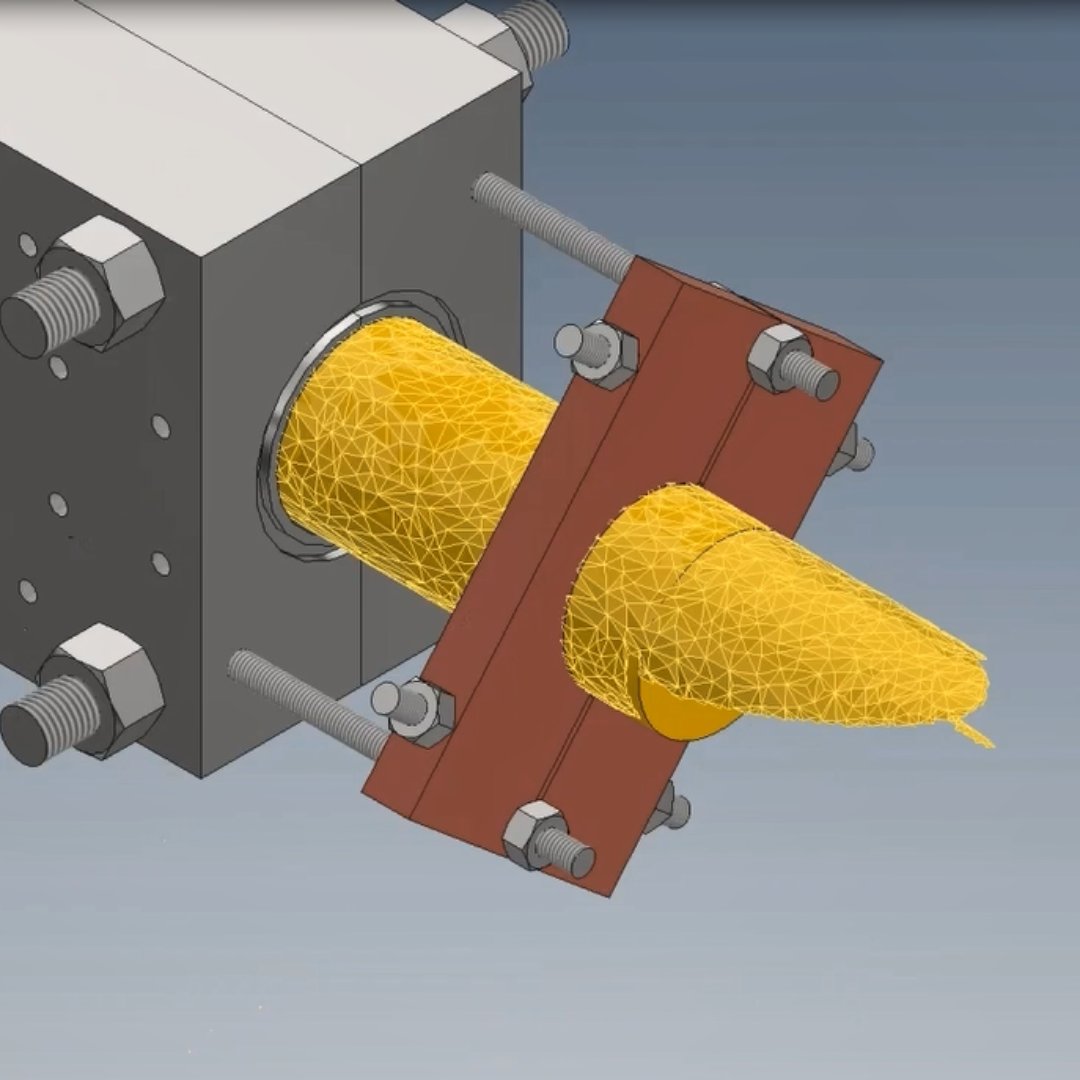

Another serious incident involved a large blind flange that was leaking due to a failed gasket. To address the problem, technicians used a method known as “wire and peen.” In this approach, wire is inserted into the flange gap and then the metal around it is peened (deformed with a hammering tool) to lock the wire in place, creating a temporary barrier. Sealant is then injected under pressure into the flange gap to stop the leak.

In this case, every time sealant was injected, the pressure forced the flange faces apart slightly, reopening the leak. The technicians repeated the process—adding more wire and peening, then reinjecting sealant—without realizing that each pressure cycle was stretching the studs holding the blind flange.

Eventually, the studs elongated to the point of failure, and the blind flange catastrophically blew off. The violent release killed multiple people. This failure could have been prevented with proper strongbacking.

Image from https://econo-seal.com/on-line-leak-sealing-on-piping-and-components/ . This image was not associated with the failure described above. It is a VERY NICE looking wire and peen job!

Strongbacking and the Hierarchy of Controls

Strongbacking is all about safety! You likely have heard of the hierarchy of safety controls:

Elimination

Substitution

Engineering Controls

Procedural Controls

Personal Protective Equipment (PPE)

With on-line leak repair, elimination and substitution are not possible, which is why the request for on-line leak repair would have been made in the first place. So the next line of defence is Engineering Controls. Strongbacking is an engineering control.

Cost vs. Safety: The Real Trade-Off

It may seem obvious to use strongbacks on every job, but the reality is more complicated. Strongbacks add time and cost, both of which are important, and Strongbacks can be the most complex and expensive part of a leak repair!

However, history shows that cutting corners comes at a much higher price: worker injuries, fatalities, and facility damage.

What we recommend

At My Engineering, this is our approach to strongbacking, and is also our recommendation for a best practice:

Start each leak repair job assuming that strongbacking is required.

Perform a structured assessment to determine if strongbacking can safely be eliminated.

Never compromise safety for cost or schedule.

This process ensures that strongbacking is never overlooked, and when it is deemed unnecessary, it’s only after rigorous evaluation.

Final Thoughts

Strongbacking is not just a technical detail—it’s a life-saving practice. By integrating strongbacks into leak repair designs, engineers provide an essential safeguard against failures.

The responsibility lies with onsite technicians, plant engineers, and contract-level engineers to ensure proper structural restraints are in place.

Stay Safe, Stay Strong—Backed.