Static Seal Showdown: Graphite Rope vs. Copper Tubing – Who Wins?

When it comes to leak repair, the choice of static seal can make all the difference. Two commonly used options are graphite rope packing and copper tubing. Both have their pros and cons, but which one truly performs better across real-world conditions? To answer this, we put them to the test and evaluated each seal across six key criteria:

Ease of installation

Durability

Compressibility

Chemical compatibility

Temperature rating

Pressure rating

Exploring the Contenders: Graphite Rope Packing vs. Copper Tubing

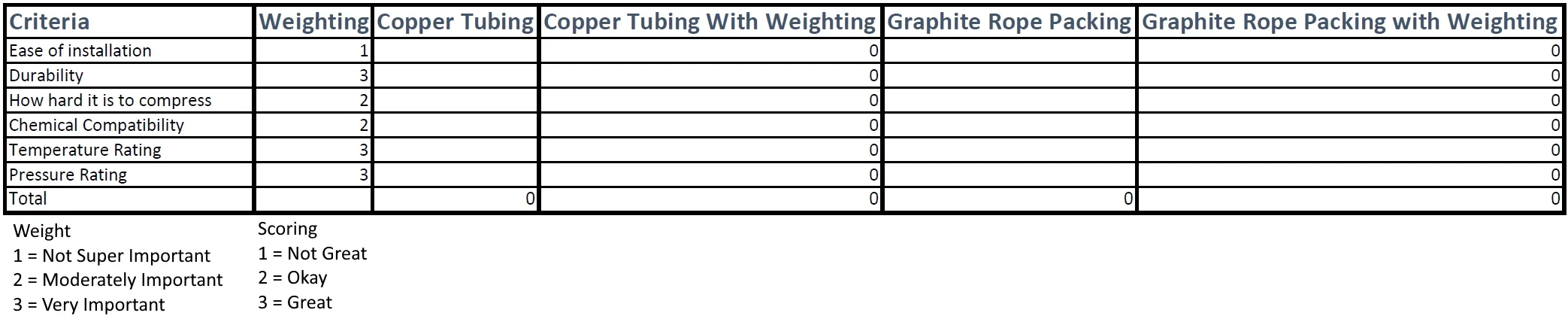

The essential criteria we used to evaluate these seals included: Ease of Installation, Durability, Compressibility, Chemical Compatibility, Temperature Resistance, and Pressure Rating. We've used a weighted decision matrix to ultimately determine which seal is the best. We assigned a weighting to each criteria in accordance with its importance. For simplicity, we chose a scale between 1-3 where 1 is Not super important, 2 = Moderately Important, and 3 = Very Important. We used a similar logic of the scoring as well where 1 = Not Great, 2 = Okay, and 3 = Great.

Criteria 1: Ease of Installation

Test Setup:

For Copper Tubing, we bent it around a ring to fit into a groove, cut it, and reshaped it for a snug fit.

Results:

Copper Tubing: Was difficult to fit, required power tools to cut, followed by reshaping. Using Copper Tubing would normally need soldering as well (extra steps).

Even though Copper Tubing is somewhat flexible, it proves to be difficult and time consuming to work with.

Test Setup:

For Graphite Rope Packing, we simply laid it into the groove, cut it with a knife, and pressed it in place.

Results:

Graphite Rope Packing: Extremely quick and easy to install.

Winner of Ease of Installation : Graphite Rope Packing

Scores:

Copper Tubing: 1

Graphite Rope Packing: 3

Criteria 2: Durability

Field tests confirmed copper tubing's susceptibility to dents during installation, compromising seal integrity. Although both materials showed some vulnerability to damage, graphite rope packing was considerably more resistant.

Test Setup:

We Lightly Struck each material with a hammer to simulate handling and installation damage, and gauge their behavior to impact.

Results:

Copper Tubing: Field tests confirmed copper tubing's susceptibility to dents during installation, compromising seal integrity.

Graphite Rope Packing: Deformed slightly but more resilient than copper.

Although both materials showed some vulnerability to damage, graphite rope packing was considerably more resistant.

Winner for Durability: Graphite Rope Packing

Scores:

Copper Tubing: 1

Graphite Rope Packing: 3

Criteria 3: Compression Difficulty

The seals must compress adequately to create an effective seal, while managing the amount of force required to achieve an effective seal.

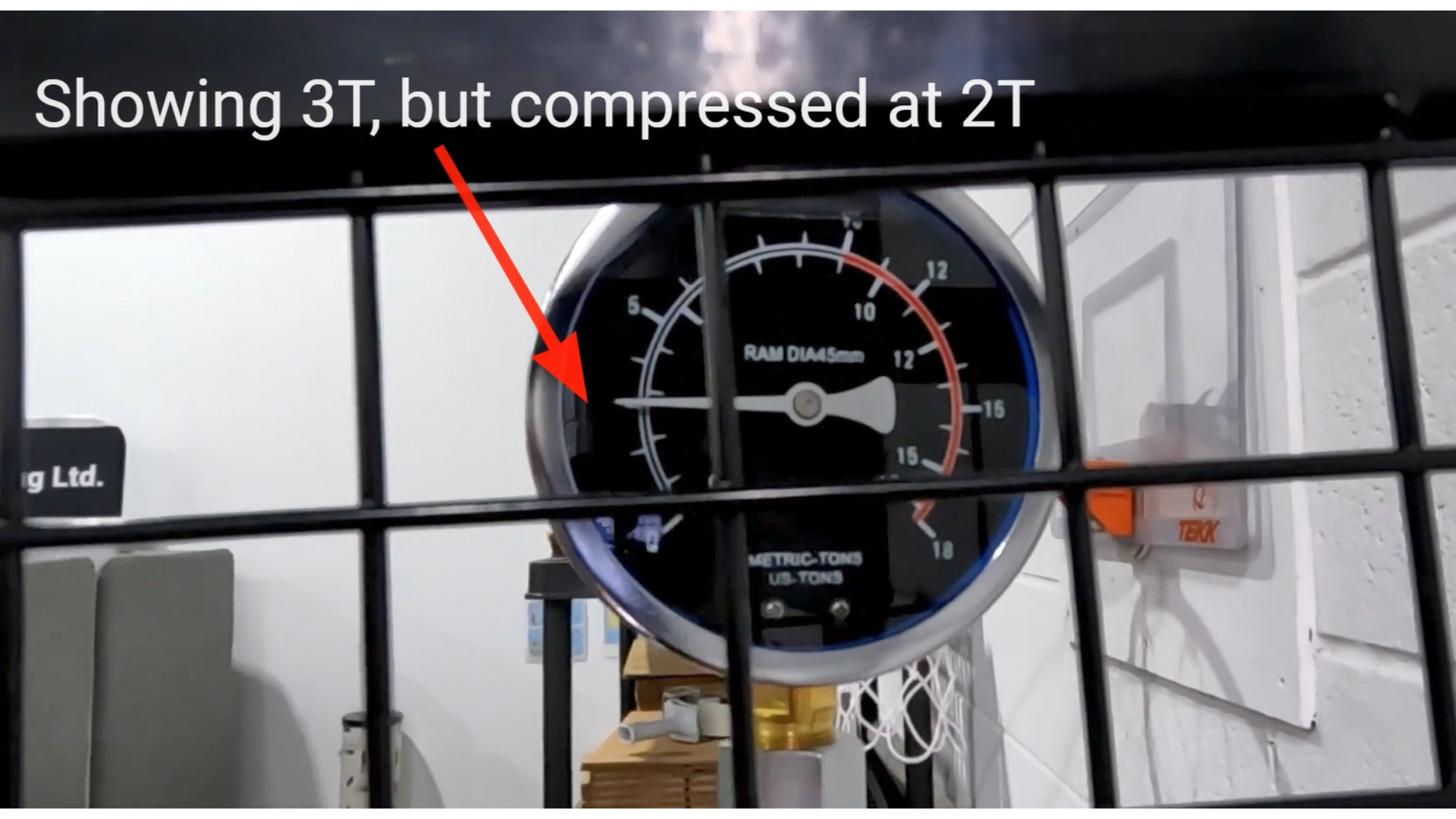

Test Setup:

We Compressed each seal in a press, to 50% of its original height using ¼-inch tubing in a ⅛-inch groove.

Results:

Copper Tubing: Reached near flush with just over 2 tons of force.

Graphite Rope Packing: Required over 5 tons of force and still resisted full compression.

Winner for Compression Dificulty: Copper Tubing

Scores:

Copper Tubing: 3

Graphite Rope Packing: 2

Criteria 4: Chemical Compatibility

Our evaluation for Chemical Compatibility was research based.

Evaluation (Research-based):

Graphite Rope Packing: Highly inert, works in most environments. The only vulnerable is to strong oxidizers like nitric acid or hot concentrated sulfuric acid.

Copper Tubing: Being a metallic material, is susceptible to galvanic corrosion, ammonia-based chemicals, and oxidizing acids.

Winner for Chemical Compatibility: Graphite Rope Packing

Scores:

Copper Tubing: 2

Graphite Rope Packing: 3

Criteria 5: Temperature Resistance

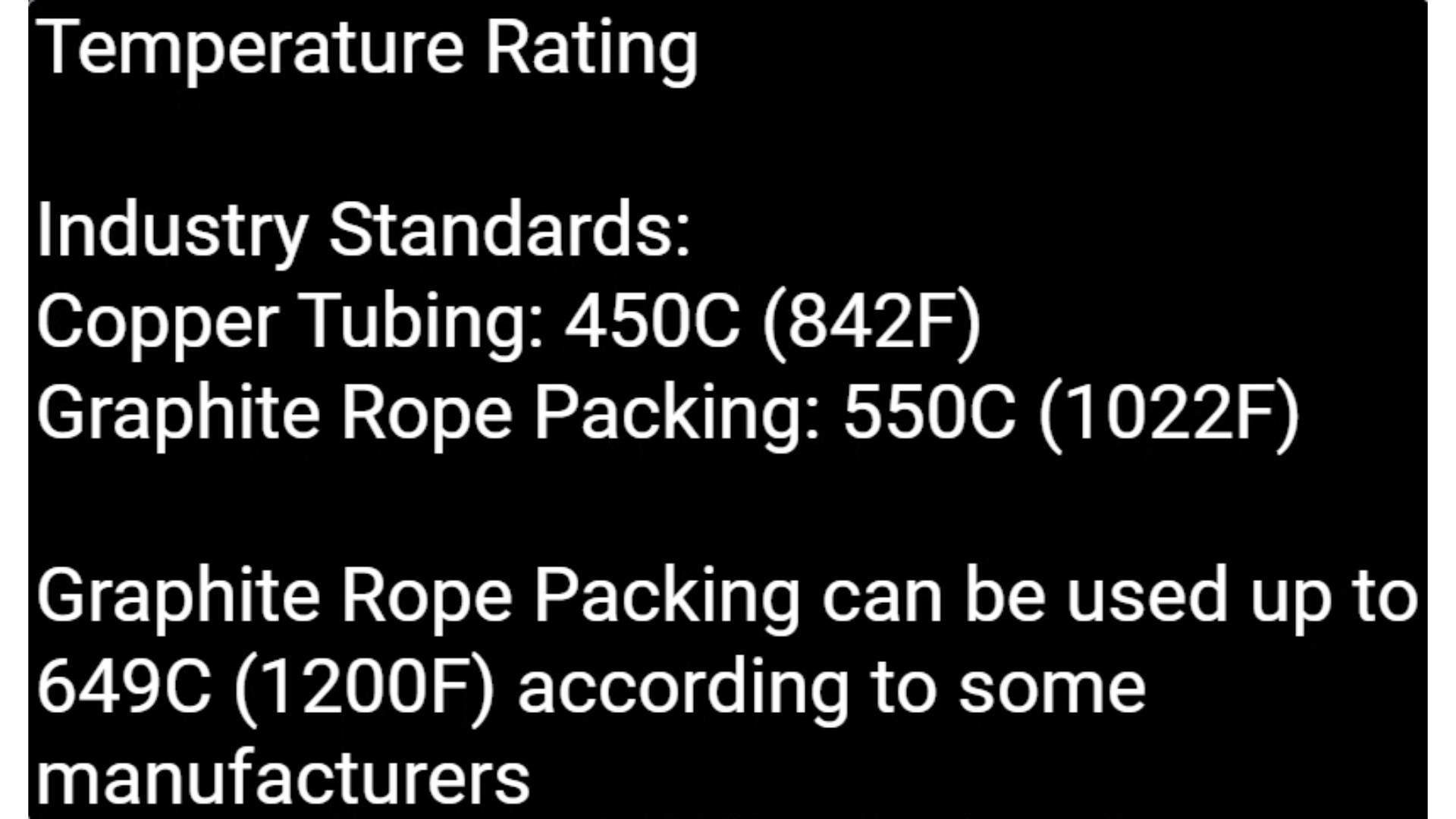

Our evaluation for Temperature Resistance was based on Industry Standard Specifications.

Evaluation (Based on Industry Standard Specifications):

Copper Tubing: Up to 450 °C (842 °F).

Graphite Rope Packing: Graphite rope packing tolerates higher temperatures. Standard use up to 550 °C (1022 °F), with manufacturer ratings up to 1200 °F.

Winner for Temperature Resistance: Graphite Rope Packing

Scores:

Copper Tubing: 2

Graphite Rope Packing: 3

Criteria 6: Pressure Rating

Our evaluation for Pressure Rating was based on Industry Practice and Manufactuer Specifications.

Evaluation (Industry Practice vs. Manufacturer Specifications):

Copper Tubing: Rated up to 1500 PSI.

Graphite Rope Packing: Typically limited to 350 PSI in leak repair enclosures (due to blowout concerns), but manufacturer specs claim up to 3000 PSI in valve applications.

*Adhesives like epoxy or Gorilla Glue are sometimes used to secure graphite packing and reduce blowout risk, but copper remains more reliable here.

Winner for Pressure Rating: Copper Tubing

Scores:

Copper Tubing: 3

Graphite Rope Packing: 1

The Final Verdict

After comprehensive evaluation, graphite rope packing edges out copper tubing with a total score of 34 against 29 in our weighted decision matrix. Though the difference isn't vast, graphite rope packing is more frequently used in leak repair due to its ease of handling and material behavior during installation.

Key Takeaways

Graphite Rope Packing is easier to install, more durable, and chemically versatile.

Copper Tubing compresses more easily and withstands higher pressures but is harder to install and more prone to damage.

Graphite Rope Packing is generally the better seal for most leak repair applications, but Copper Tubing still has its place where higher pressure tolerance is critical.

*The final choice should always be made in consultation with the technician or company handling the leak repair, as application-specific factors can change the recommendation.

Conclusion: Choosing the Right Seal

While this analysis highlights the advantages of graphite rope packing, it's crucial to consult with technicians for their insights on specific applications. Their expertise often guides the choice of seal type, ensuring optimal performance.

We hope this examination of graphite rope packing vs. copper tubing has been insightful.

If you found this information useful and want to learn more about advanced leak repair methods, don’t forget to subscribe to our channel or join our mailing list. We share new insights and tutorials regularly—stay ahead of your maintenance challenges by staying informed.