Laser Scanning for Pipe Inspection: A Faster, More Accurate Alternative to Traditional Methods

Pipeline integrity is critical in industries such as oil & gas, petrochemicals, and utilities. Traditionally, inspection methods for assessing corrosion, pitting, and wall loss have relied on manual depth gauges, pit gauges, and ultrasonic testing (UT). While effective, these methods can be time-consuming, labor-intensive, and prone to human error.

With the advancement of 3D laser scanning technology, engineers can now capture defects with micron-level accuracy, analyze them digitally, and generate comprehensive reports far faster than ever before. In this article, we’ll walk through a real-world example of using a laser scanner (KSCAN X) in combination with Geomagic Control X to analyze pipe pitting — and compare it against traditional inspection methods.

Step 1: The Scanning Process

We begin with an 8-inch yellow jacket pipe section showing visible pitting. Using the Scanology KSCAN X blue light scanner, the surface was digitized at an accuracy of approximately 0.001” (25 microns).

Key features of the scan setup:

Scale Bar Calibration: Ensures the data maintains high accuracy throughout the capture.

Target Registration: Automatically aligns reference points for consistent measurements.

Automated Background Removal: Eliminates unwanted geometry, like the floor, for a clean dataset.

The result is a high-resolution point cloud/mesh showing not only the main pit but also minor surface defects that would likely be missed during manual inspection.

Step 2: Analysis in Geomagic Control X

Once scanned, the data is imported into Geomagic Control X for analysis. The process involves:

Alignment – Attaching a coordinate system to the scan data.

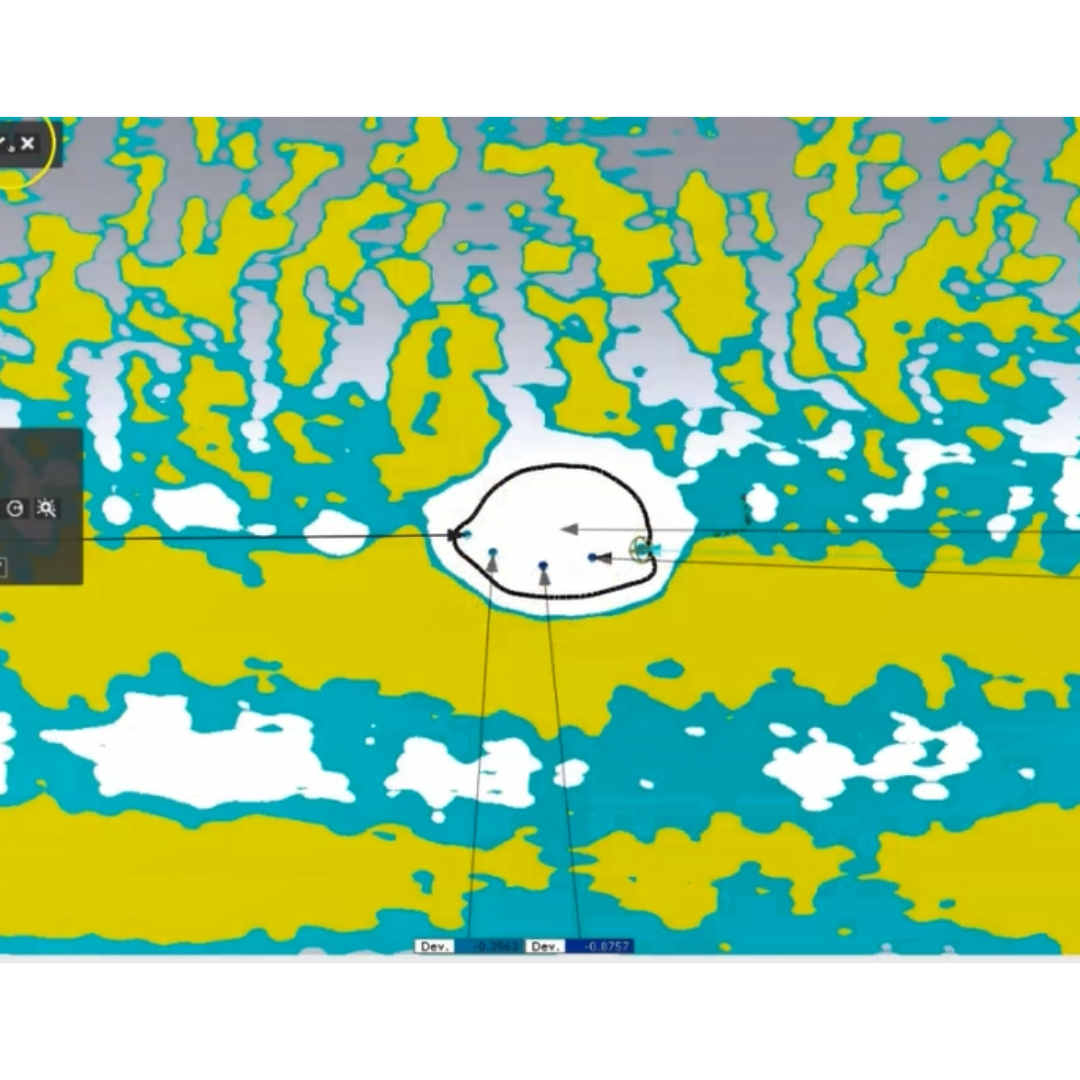

Deviation Location Tool – Comparing the scanned surface against a fitted reference plane.

Defect Characterization – Measuring depth, area, and volume of the corrosion pit.

In this demonstration, the major pit was measured at a maximum depth of 1.40 mm with an affected area of 172 mm².

Advanced Workflow: Riverbed Analysis

Beyond simple measurements, engineers can perform a riverbed analysis, which replicates the manual approach of plotting depth readings across the pit. By generating a fitted CAD surface and sampling comparison points, a defect profile can be mapped in detail — enabling accurate fitness-for-service (FFS) or failure analysis studies.

Advantages Over Traditional Inspection Methods

1. Speed and Efficiency

Laser scanning captures the entire geometry in minutes.

Manual gauges require dozens of individual measurements, often taking hours.

2. Accuracy and Repeatability

Scanners achieve sub-millimeter accuracy consistently.

Manual readings depend on operator skill and may vary between inspectors.

3. Comprehensive Data

A complete 3D record of the pipe is created, capturing all defects at once.

Traditional methods only measure what the operator chooses, potentially overlooking smaller damage.

4. Digital Reporting & Traceability

Data is easily exported into standardized reports for compliance, audits, or client deliverables.

Historical scan data can be compared over time to track corrosion growth rates.

5. Safer Inspections

Engineers spend less time in hazardous environments since most analysis can occur in the office.

Fieldwork is reduced to scanning, while in-depth evaluation can happen remotely.

Conclusion

By combining laser scanning with powerful inspection software like Geomagic Control X, engineers gain a faster, more reliable, and more comprehensive solution for pipe inspection compared to traditional gauges or manual methods.

This technology not only improves accuracy but also supports predictive maintenance strategies, enabling operators to make better-informed decisions about pipeline integrity and service life.

As industries continue to demand higher standards for safety and efficiency, laser scanning is rapidly becoming the preferred method for corrosion and defect assessment.

Interested in learning more? Contact us at info@myeng.ca for a demo or consultation on how 3D scanning can optimize your inspection workflows.