Seal the Deal: Understanding Perimeter Seals in Leak Repair Enclosures

In this guide on perimeter seals, a crucial component in leak repair enclosures, we'll delve into the three primary types of perimeter seals: the single, double, and triple perimeter seals. We'll explore what perimeter seals are, their advantages over other methods, and provide tips for optimal installation.

What is a Perimeter Seal?

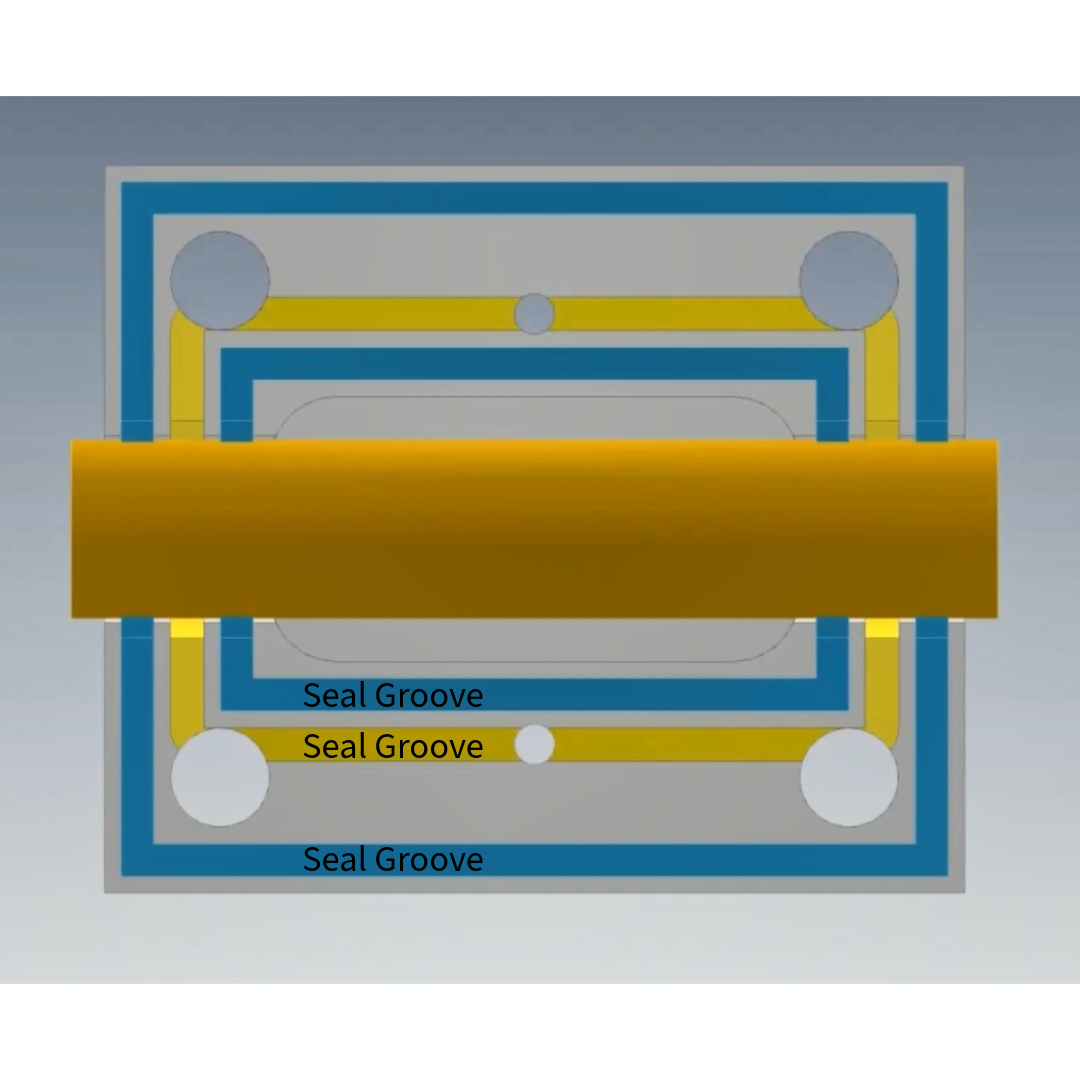

Perimeter seals are designed to run through the enclosure bores and wrap around the perimeter, creating a continuous barrier against leaks. They primarily utilize injectable sealant, which is introduced into a groove crafted into one half of the enclosure. This unique engineering allows enclosures to split into multiple pieces, securely bolting onto different installations and managing leak paths along these split lines efficiently.

Enclosures are split into multiple pieces, to enable fixturing to the leaking item. This results in what is called a “Split Line”. Each Split Line creates a leak path and must be sealed.

Types of Perimeter Seals

Single Perimeter Seal: This seal features one injection groove circling the enclosure and bores. There is usually an inner static seal (packing or tubing) on each of the bores, on the inside of the injection groove, that prevents sealant from extruding into the cavity. An additional static seal or peeing groove, is added to the outside of the injectable sealant groove on the bores to prevent sealant from extruding out of the enclosure. Peening is a technique involving a chisel that bends over a metal lip milled into the enclosure to create a physical barrier against extrusion. Modern machining advances have bolstered the popularity of single perimeter seals, especially with tight-fitting plate boxes.

Double Perimeter Seal: Building on the single seal's foundation, this variant adds another static seal groove around the perimeter, further preventing sealant from leaking into the cavity. Peeing the split line around the perimeter might also serve as a safeguard if sealant attempts an escape towards the outside.

Triple Perimeter Seal: The most robust seal available, incorporating an inner static seal, a central injection groove, and an outer static seal to ensure maximum containment. However, this enhanced security increases the enclosure size and requires more force to compress the packing fully. This choice is optimal for high reliability. It is also beneficial on enclosures that are manufactured using welding processes, and/or heat treatment that may cause the splitlines to distort from being perfectly flat. The additional static seal grooves prevent sealant from extruding into and out of the enclosure.

When to Use Which Seal

Choosing between single, double, and triple perimeter seals often depends on the type of enclosure. For machined plate box styles, single grooves typically suffice due to the seamless joining of flat surfaces. In contrast, fabricated enclosures, requiring welding or heat treatment, benefit from the triple seal’s packing grooves to counteract non-flat split lines.

Advantages of Perimeter Seals

Perimeter seals offer some key benefits over void fills:

Cost-Effectiveness: They need less sealant than a void fill, making them a more economical and quicker installation choice.

Reduced Injection Risks: There's a minimal chance of injecting sealant into the leaking pipe and into the service stream (also known as mainlining).

Safety in Pressure Management: Perimeter seals apply less external pressure during injection, reducing risks for long enclosures or thin piping.

Pro Tip for Installation

For effective enclosure design under active leaking conditions, it is always a good idea to incorporate a vent port. This feature helps manage pressure within the enclosure during installation, simplifying the process and preventing unwanted blowouts of packing from the bores or grooves.

Conclusion

By understanding and implementing the right perimeter seal, you can significantly enhance the reliability and safety of your leak repair enclosure projects. For more insights into online leak repair, explore our other guides and tutorials.

If you found this information useful and want to learn more about advanced leak repair methods, don’t forget to subscribe to our channel or join our mailing list. We share new insights and tutorials regularly—stay ahead of your maintenance challenges by staying informed.