Cutting Downtime, Cutting Costs: How 3D Scanning Improves Industrial Replacement Projects

Industrial piping and pressure vessels are critical assets in process, energy, and mining industries. Their replacement and refit projects often involve complex geometries, congested layouts, and tight outage windows. Traditional measurement and design methods introduce significant risks of error, schedule overruns, and rework. The advent of 3D scanning combined with engineering design software offers a data-driven, digital-first approach that reduces uncertainty, improve accuracy, and delivers measurable return on investment. This article outlines the challenges of legacy practices, the features of modern 3D scanning and modeling workflows, and the advantages and benefits these technologies provide in driving projects to successful outcomes.

Challenges with Traditional Methods

Manual Measurement & Documentation: Conventional approaches rely on manual field measurements, tape dimensions, and 2D drawings. In congested piping corridors or vessel installations, capturing accurate tie-in points is error-prone and labor-intensive. Even small inaccuracies cascade into costly rework.

Limited Visualization: 2D drawings cannot fully represent spatial constraints of piping systems, support structures, and vessel connections. Engineers and installers face surprises in the field, leading to clashes, change orders, and safety risks.

Downtime & Safety Risks: Plant outages are expensive. Any misalignment during refit or replacement extends downtime, increases labor costs, and exposes workers to hazardous environments. Repeat site visits further escalate both safety risks and project costs.

Features of 3D Scanning and Engineering Software

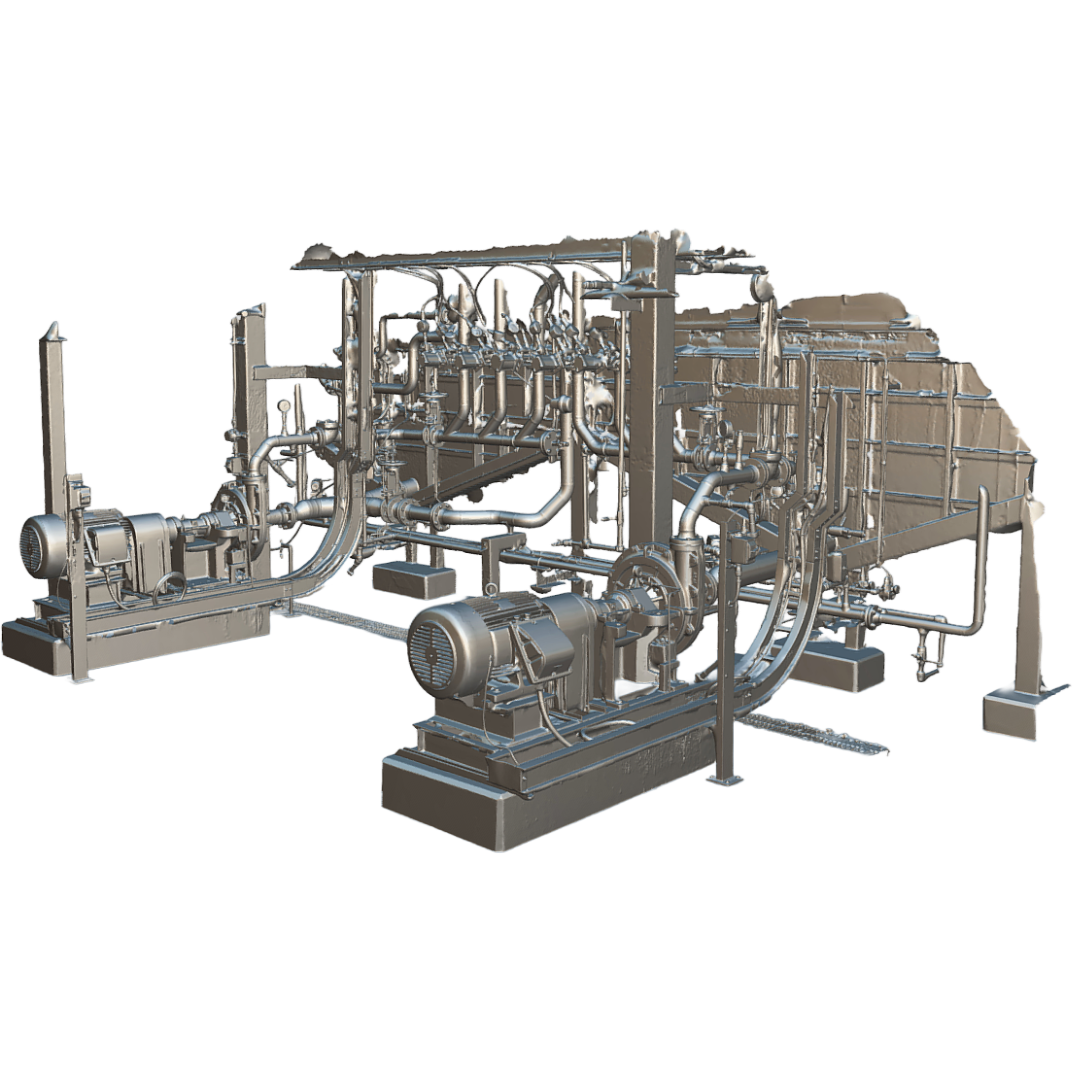

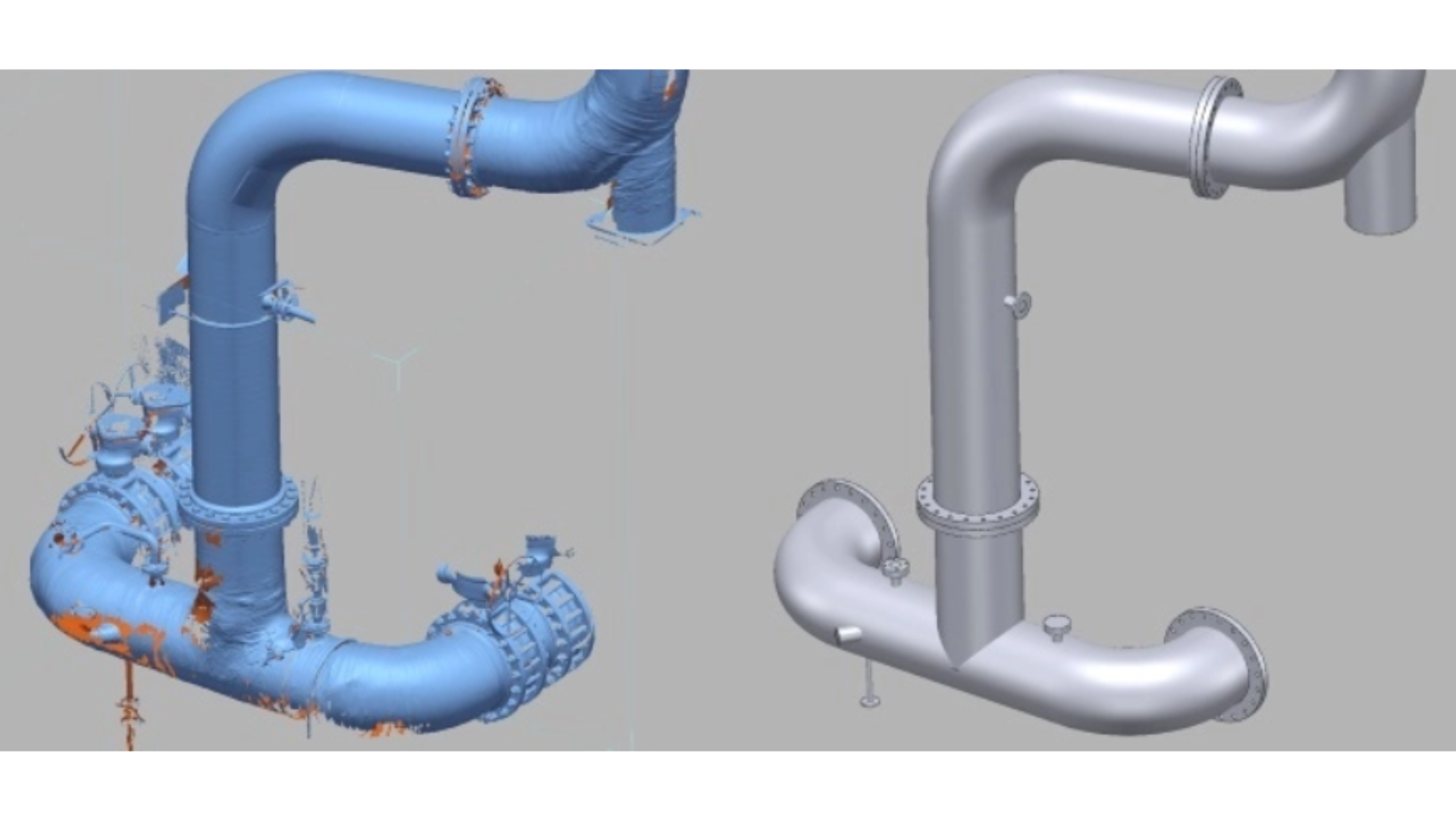

High-Resolution As-Built Capture: Laser scanners, handheld metrology systems, and mobile SLAM devices generate dense point clouds of plant areas and components, with a high level of accuracy. This digital capture replaces subjective manual measurements with objective spatial truth.

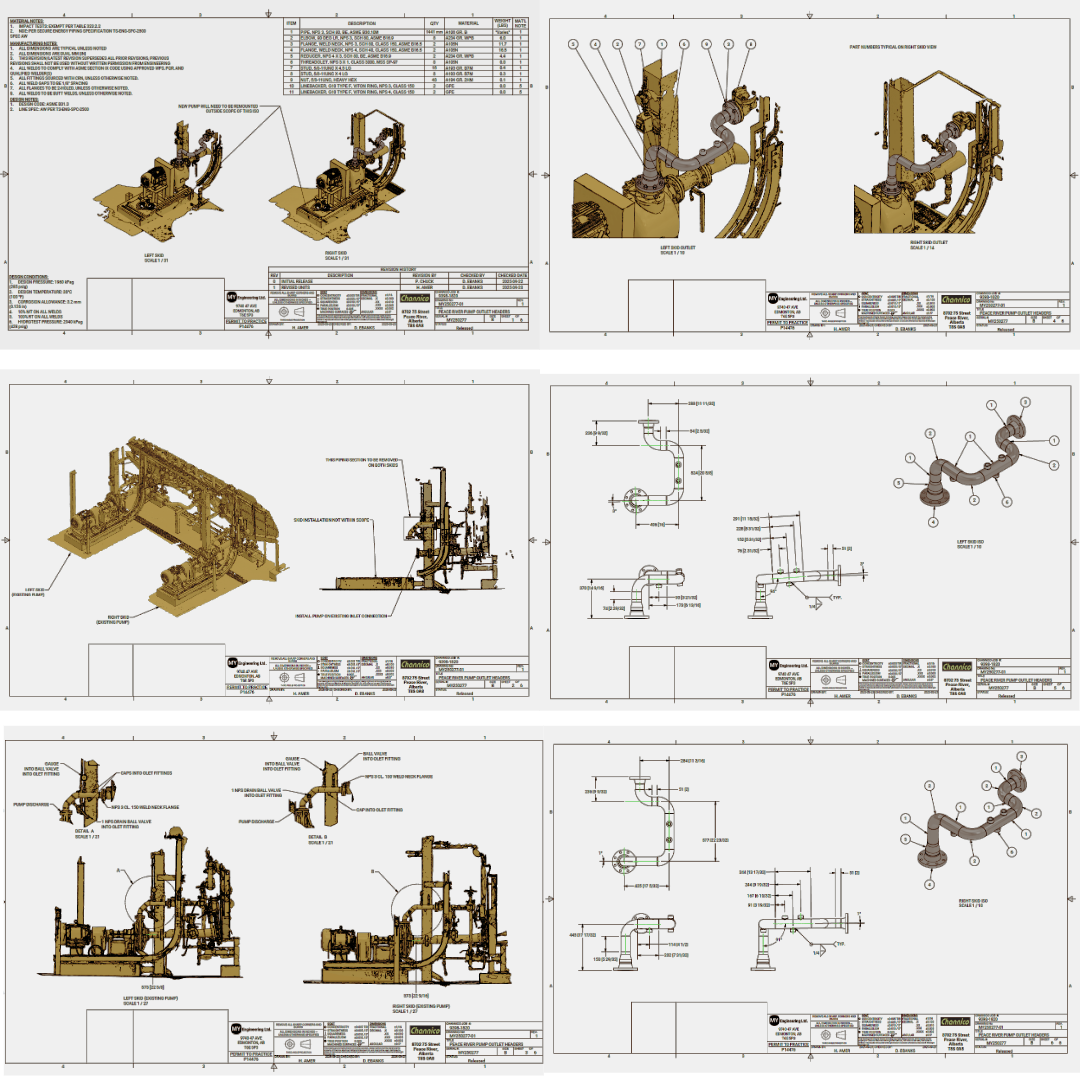

Scan-to-BIM / CAD Modeling: Point clouds are processed into intelligent 3D models (BIM or CAD). Pipe extraction and surface reconstruction create an accurate digital twin of piping, vessels, and supporting infrastructure.

Clash Detection & Prefabrication: Engineering design software leverages these models for interference checks, constructability reviews, and prefabrication planning. Replacement spools or vessel segments can be shop-fabricated with confidence.

Integration with Engineering Workflows: Scanned models integrate seamlessly with platforms such as AutoCAD Plant 3D, AVEVA E3D, or Solidworks. This integration supports advanced simulation, tie-in alignment, and lifecycle documentation.

Advantages Over Traditional Methods

Accuracy & Reliability: 3D scanning captures every angle and dimension, eliminating guesswork and reducing human error. Precise tie-in measurements allow “right-first-time” installations.

Safety & Accessibility: Operators reduce time spent in confined or hazardous spaces. Complex or inaccessible areas can be captured remotely, minimizing risk.

Speed of Execution: What once required weeks of manual survey is now accomplished in days—or even hours—using 3D scanning. This accelerates the entire design-to-installation workflow.

Reduced Field Rework: Prefabricated piping or vessel components fit on first attempt, reducing costly field modifications and welding hours. Clash-free design reduces construction uncertainty.

Benefits and Value

Cost Savings

Reduced Rework: By capturing precise conditions with 3D scanning, engineers can design replacement piping and vessels that match the real environment exactly. This accuracy allows prefabricated components to fit correctly at time of installation, minimizing unexpected adjustments and avoiding costly field modifications and wasted materials.

Outage Reduction: Faster turnaround translates to millions saved in downtime avoidance for refineries or process plants.

Time Compression

Projects requiring multiple site visits are condensed into a single scanning mobilization.

Digital models accelerate design approvals, fabrication sequencing, and installation planning.

Enhanced Asset Management

Digital twins provide documentation for future modifications.

Asset integrity inspections are faster and more accurate, improving vessel and piping lifecycle management.

Quantifiable Return on Investment

Return on investment is realized through:

Fewer Change Orders (Unknown conditions requiring field fits)

Shorter Schedules (outage times reduced)

Safer Operations (fewer man-hours in high-risk zones)

Real World Example

Fabrication and Replacement of Piping in an Offshore Vessel

Source: https://www.artec3d.com/cases/replacing-pipe-in-offshore-vessel

A fractured, 15-meter vertical pipe aboard a West Africa–operating FPSO had to be replaced urgently, inside a cramped compartment roughly 18 m high × 10 m long × 3 m wide and packed with equipment. Asian Sealand Offshore & Marine partnered with Artec’s team to capture the as-built geometry safely and precisely. They combined long-range LiDAR (Artec Ray) to map the full space and adjacent room with handheld scanning (Artec Leo) to capture fine details and obstructed areas; rope-qualified technicians even rappelled the pipe with the Leo to reach tight spots. The Ray data was registered target-free and auto-aligned; Leo data was overlaid and globally registered to minimize error accumulation over the full height.

From the scan, engineers produced accurate models and isometric drawings using Geomagic Design X (including Pipe Wizard) to fabricate the replacement spool. The workflow enabled planning of removal and installation sequencing in the congested space and avoided collateral impacts on nearby equipment.

Crucially, scanning and processing were completed in two days by a four-person onboard team while the FPSO stayed in operation—de-risking the job and compressing schedule without additional outage. The result was a right-first-time fit-up and a safer, more predictable replacement in a setting where traditional manual measurement would have been slow, hazardous, and prone to rework.

Conclusion

3D scanning and advanced engineering design software transform industrial piping and vessel replacement projects from high-risk undertakings into predictable, data-driven operations. By providing accurate as-built data, enabling precise engineering, and supporting safer, faster installation, these technologies deliver significant ROI in both capital and operating expenditures. As industry demand for reliability and efficiency grows, adopting 3D scanning workflows is no longer optional—it is a competitive necessity.