Why Enclosures Can Move After Installation: Hydraulicing Explained

When repairing leaks, one of the unexpected challenges you might face is enclosure movement after installation. This phenomenon is caused by internal pressure imbalances and is commonly referred to as Hydraulicing.

Hydraulicing can be difficult to visualize, but it’s crucial to understand. Identifying it early ensures you know when to add restraints (strongbacks) to keep the enclosure secure. In this article, we’ll break down the physics behind hydraulicing, walk through practical examples, and provide formulas you can use to quickly assess risk in the field.

The Physics of Hydraulicing

At its core, Hydraulicing is all about forces and balance. According to Newton’s First Law, for something to stay put, the sum of all forces acting on it must equal zero. If they don’t balance, movement occurs. In leak repair, we don’t usually measure force directly — instead, we measure pressure. Fortunately, these two factors are related:

Force = Pressure × Area

Inside an enclosure, the pressure is uniform, acting equally on all surfaces. But what matters most are the end faces where the enclosure lands. If the Faces around the landing areas are of different surface areas and don’t match, the forces on each area won’t match either — and that’s when hydraulicing occurs.

Finally, remember that movement happens because of this fundamental equation:

Force = Mass × Acceleration

A net force greater than zero means the enclosure will accelerate (move) in the direction of that force.

Illustrative Example: Single Bore Enclosure

Take, for instance, an enclosure over a blind flange as pictured here. This setup naturally leans to one side due to pressure differences caused by surface area discrepancies. Assume the pressure fills the enclosure uniformly; for a balanced system, you'd want equal pressure on either side.

Suppose the left side has 130 square inches compared to 114 square inches on the right, with a pressure of 100 PSI. The side with no bore (left) experiences 13,000 pounds of force, while the bore side (right) experiences 11,400 pounds. The resultant net force is 1,600 pounds driving the enclosure towards the larger surface area on the left, similar to the mechanics of a bottle rocket.

Two Bore Enclosure Scenario

Imagine an enclosure with two different-sized bores (12 inch and 6 inch). It will inherently move towards the smaller bore, similar to single bore dynamics but with discrepancies due to differing internal surface areas. Larger surface areas translate to greater force, directing movement towards less resistant sections.

Calculated areas:

Left Bore: 12-inch side: 54 in²

Right Bore: 6-inch side: 148 in²

With internal pressure at 100 psi:

Force on left 12-inch side = 5,400 lbs

Force on right 6-inch side = 7,300 lbs

That’s a net force of over 9,000 lbs pulling the enclosure toward the smaller bore on the right.

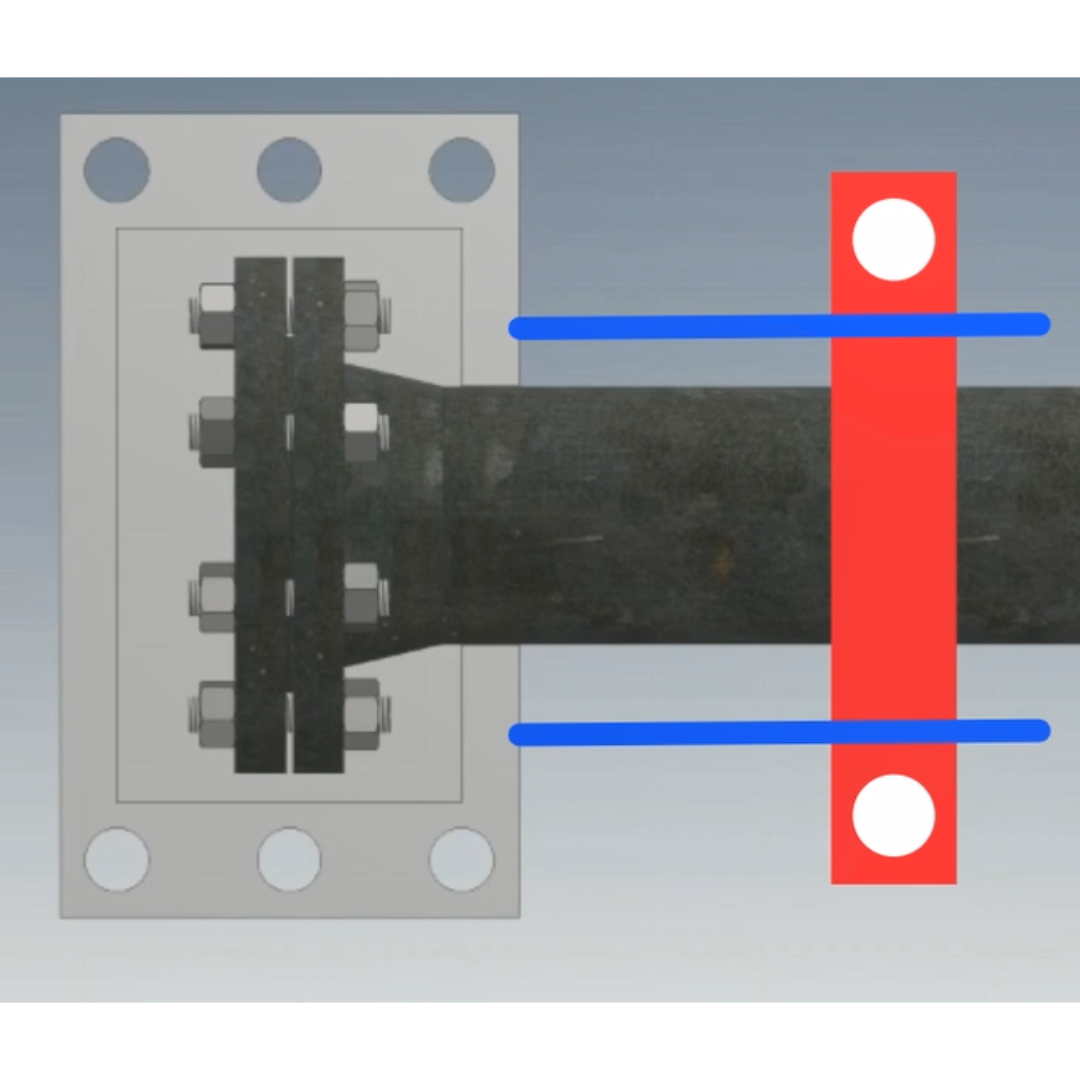

Another Common Example

Flange-to-pipe enclosures: These enclosures can shift toward the pipe side. To prevent this, a Strongback or flange tongue is often added. This both prevents movement and allows for sealant injection into the flange gap, reducing leakage risk through stud holes.

Why Hydraulicing Matters

Understanding hydraulic force dynamics within enclosures helps anticipate and mitigate potential movement. Practitioners can better equip themselves against these challenges by implementing necessary restraints, thus ensuring successful, stable installations.

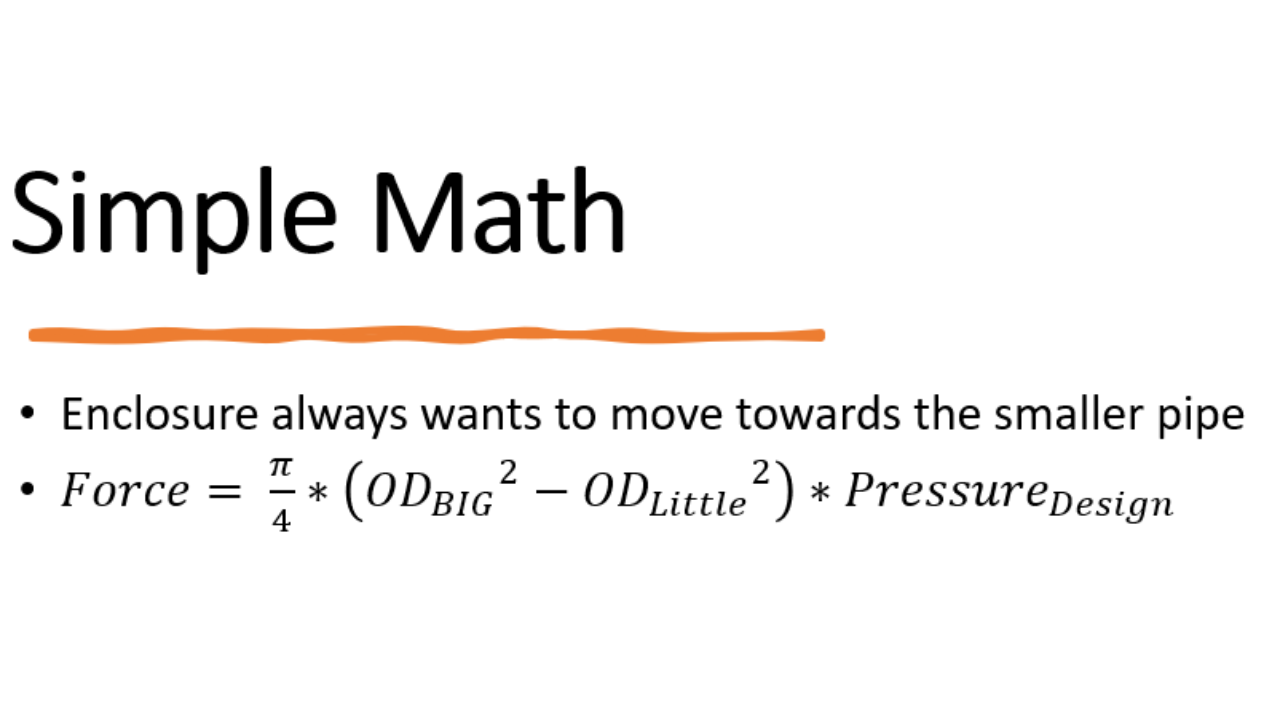

To quickly calculate net hydraulicing force in these scenarios, use the formula shown here:

OD1OD_1OD1 = larger bore diameter

OD2OD_2OD2 = smaller bore diameter

Design Pressure = internal pressure in the enclosure.

👉 The net force always points toward the smaller bore.

If bore sizes aren’t equal, the forces won’t balance, and the enclosure will want to slide or even launch itself.

The solution? Restraints (Strongbacks). These keep the enclosure stable and ensure the seal holds under pressure.

Key Takeaways

Pressure is uniform inside the enclosure.

Force = Pressure × Area.

If bore areas differ, forces don’t balance.

Net force always drives the enclosure toward the smaller bore.

Use strongbacks or restraints to keep enclosures stable when hydraulicing is present.

Conclusion

Hydraulicing is one of the most important checks when planning or installing an enclosure. By measuring both bores, applying the quick formula, and checking for imbalances, you can predict when restraints are necessary — preventing costly failures and ensuring a safe, reliable repair.