From Downtime to Digital Uptime: The Value of Building a Legacy Parts Library

Across every sector—energy, mining, manufacturing, and transportation—industrial facilities depend on legacy equipment. These machines, often decades old, continue to perform critical tasks but rely on components that are increasingly difficult or impossible to source. OEMs and plant operators frequently face the same dilemma: how do you maintain or rebuild equipment when the original CAD models and drawings no longer exist?

This is where 3D scanning, reverse engineering, and digital data management converge to deliver lasting value. By capturing precise digital representations of physical components and storing them in a structured digital library, organizations can build a living database of their mechanical DNA—ready for rapid reproduction, redesign, or performance optimization at any time.

From Physical Assets to Digital Inventory

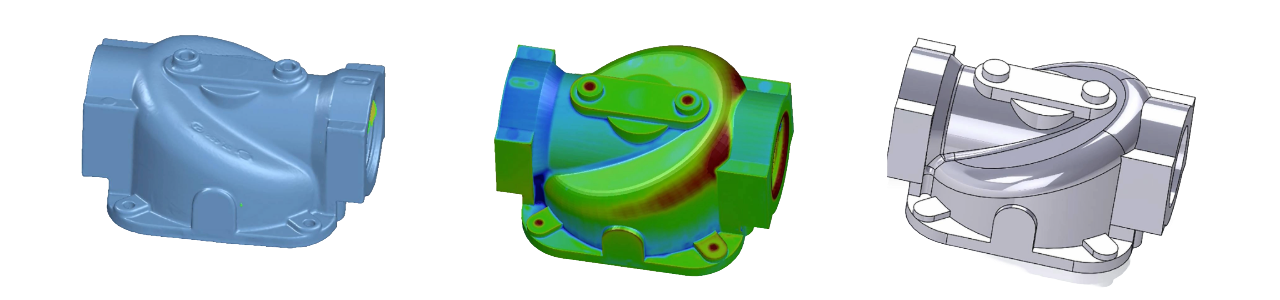

A digital part library is a centralized repository of 3D-scanned, reverse-engineered models that document every critical component of an asset fleet or product line. Using metrology-grade 3D scanners—such as structured-light or laser-based systems—engineers capture exact surface geometry and dimensions.

That data is processed through reverse engineering software like Geomagic Design X, Artec Studio, or QuickSurface to create fully parametric CAD models. These files can then be cataloged, version-controlled, and stored within a Product Lifecycle Management (PLM) or Asset Management system.

The result is a digital twin ecosystem—an on-demand library of verified models that can be used for inspection, redesign, additive manufacturing, or conventional machining. Instead of searching through archives or recreating drawings from scratch, teams can access a validated, production-ready file with a single click.

Features of a Digital Part Library

Advantages for OEM’s

Faster Reproduction and Reduced Lead Times

OEM’s can reproduce discontinued or customer-specific parts in a greatly reduced timeline. A digital library eliminates dependency on aging drawings or physical samples.

2. Design Agility and Innovation

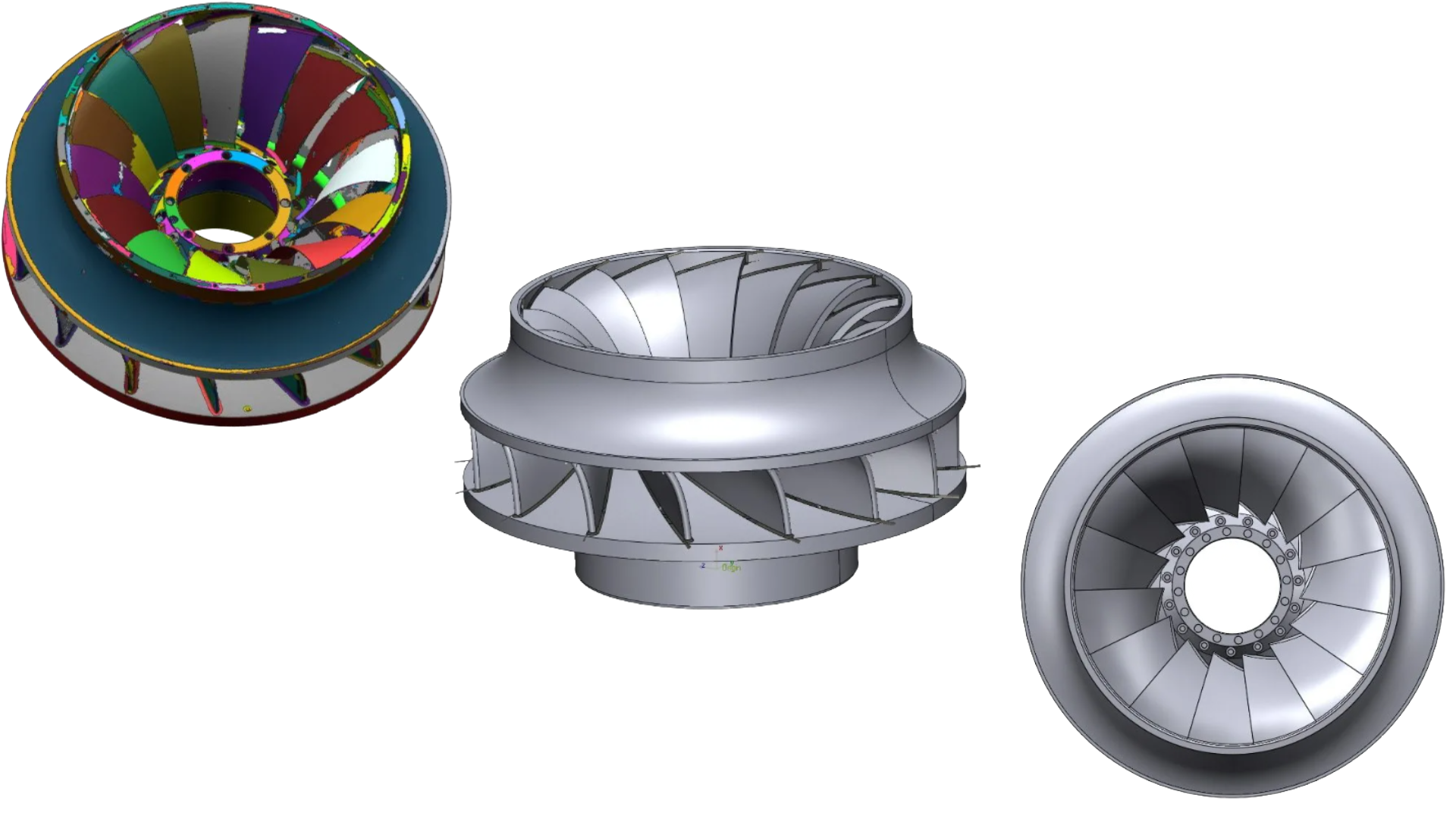

Once captured, digital models can be modified for performance improvement—such as redesigning impellers for better fluid dynamics or updating housings for lighter materials.

3. Customer Retention Through Digital Support

OEMs offering digital spare-part archives or scanning-as-a-service strengthen customer loyalty and differentiate themselves with proactive lifecycle support.

4. Reduced Inventory Costs

Instead of stocking every physical spare, OEMs can store a verified digital master and produce components on demand using CNC or additive methods.

Benefits for Industrial Facility Owners

Zero-Downtime Readiness

With a digital catalog of critical components, facilities can reproduce replacement parts immediately—reducing downtime.Asset Life Extension

Reverse-engineered digital twins enable operators to keep legacy systems in service long after OEM support ends, extending ROI on capital equipment.Predictive Maintenance and Data Analytics

Digital records can track wear over time by comparing new scans against baseline models, supporting condition-based maintenance.Cross-Functional Collaboration

Engineers, suppliers, and maintenance teams can share standardized 3D data securely—streamlining communication and eliminating costly errors.

Strategic Value

Digitizing legacy parts is more than an operational improvement—it’s a strategic investment in resilience and agility.

For OEM’s, the return on investment comes from shorter engineering cycles, lower rework rates, and new revenue streams from digital spare-part services.

For Operators, the payoff is reduced downtime, lower procurement costs, and longer asset lifespans.

Companies adopting digital part libraries report:

Up to 80% reduction in replacement part lead time

60–70% lower rework and measurement costs

Improved overall equipment effectiveness (OEE) through faster response to component failure. In short: every scan today becomes a competitive advantage tomorrow.

Conclusion: The Digital Blueprint for Industrial Continuity

In an era of supply chain volatility and rising maintenance costs, data is the new spare part. Building a digital library of legacy components gives OEMs and industrial facility owners the ability to reproduce, adapt, and evolve with speed and precision.

The future of maintenance and remanufacture is not reactive—it’s data-driven, on-demand, and digitally empowered. With every scanned component, you’re not just preserving history—you’re engineering the future.