What is a Leak Repair Enclosure?

You’ve got a leak in your facility, but it’s going to be a costly and time consuming repair, and you cannot afford to shutdown. What options do you have? A leak repair enclosure may be just the solution!

In this article, we'll delve into what a leak repair enclosure is, its importance, and how it functions.

What is a Leak Repair Enclosure?

A leak repair enclosure is a specially engineered device tailored to contain an active leak or to prevent potential leaks in damaged sections of pressure equipment. You might also hear it referred to by other names in the industry, such as a leak box, a clamp, a coffin, or an engineered pressure enclosure.

When a defect is identified in a pressure component, the ideal solution is to replace the damaged pieces. However, this often requires shutting down the system or bypassing the problematic section, both of which can be costly and time-consuming. Instead of these traditional methods, many facilities opt for online repairs with the help of leak repair enclosures.

Components and Functionality

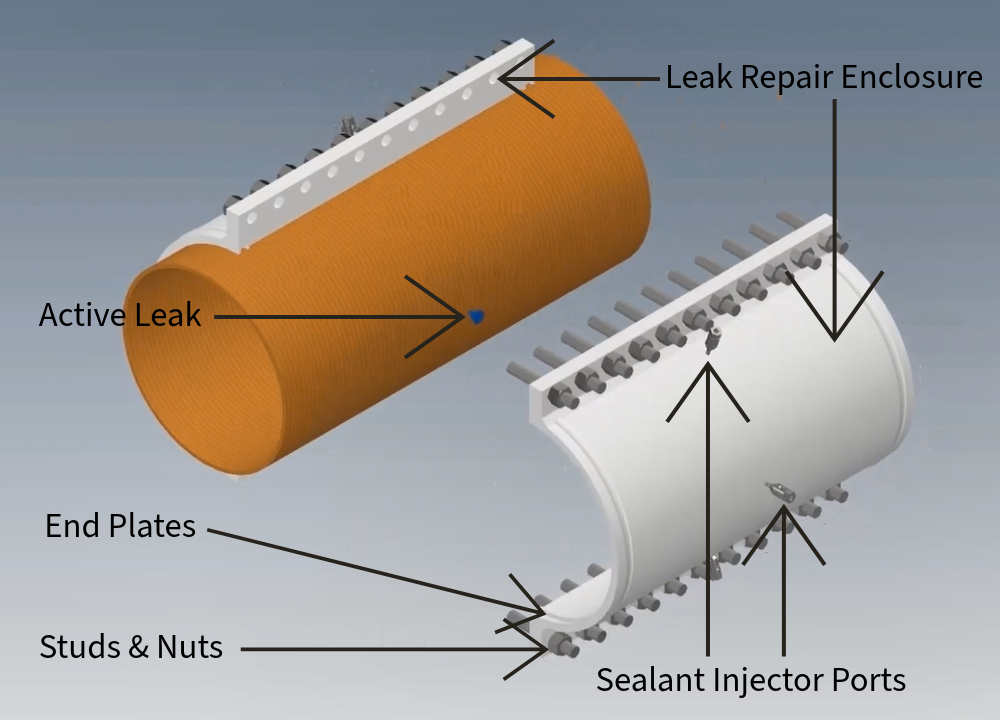

Let’s take a closer look at a typical leak repair enclosure:

This device usually consists of two identical halves that are bolted together using studs and nuts. In many cases, the two halves are identical yet mirrored, except for perimeter seal enclosures, which feature seal grooves around the exterior of one half.

Key components include end plates that snugly fit against the pipe, bolting lugs, and a top plate (or shell) that extends outward. These features are all designed to effectively contain pressure.

On the exterior of the enclosure, there are ports for sealant injectors. These ports allow sealant to be pumped under pressure into the enclosure’s void or seal grooves, creating an effective seal.

How It Works

The enclosure is bolted around the compromised pipe section. Sealant is injected into the cavity, filling the space between the enclosure and the pipe, which forms a seal. Think of it as an engineered band-aid over the failed section. This setup acts as a temporary solution, ensuring pressure containment until a permanent repair can be executed during scheduled maintenance.

Versatility and Applications

Leak repair enclosures are highly versatile, adaptable to numerous scenarios and piping components, such as straight pipes, elbows, tees, flanges, and valves. Their adaptability makes them ideal for various geometries where pressure containment is critical.

If you found this information useful and want to learn more about advanced leak repair methods, don’t forget to subscribe to our channel or join our mailing list. We share new insights and tutorials regularly—stay ahead of your maintenance challenges by staying informed.