Crack the Code: Leak Repair Terms Every Pro Should Know

If you’ve been watching our leak repair videos and found yourself wondering what some of the terms mean, you’re not alone. Leak repair involves a lot of specialized language—terms like “bore seal,” “void injection,” or “crunch teeth” can sound confusing without context. This glossary was created to help. It defines common leak repair terminology in plain language, with diagrams and examples to make things easier to understand. Whether you're new to the field, involved in planning, purchasing, or just curious about how industrial leak sealing works, this guide will give you the foundational knowledge to follow along with confidence.

Bore Peening

Bore peening is a sealing technique used to create a physical barrier that prevents sealant from being extruded past the seal. A technician uses a peening chisel, typically powered by a pneumatic hammer, to deform the lip/groove on the enclosure against the pipe it is installed on.

On the enclosure itself, either a peening lip (a small raised edge) or a peening groove (a recessed channel) is machined into the bore. These features provide a small metal ridge that the technician folds over against the pipe to create a physical barrier to prevent sealant extrusion.

Peening Lip: A raised metal lip on the surface of an enclosure bore that is designed to be bent over, using a peening chisel, against the pipe surface.

Peening Groove: A recessed area machined into the bore of an enclosure that provides a metal surface to be deformed against the pipe using a peening chisel.

Bore Seals

A primary sealing element located inside the bore of the clamp or enclosure that contacts the pipe surface.

Single Seal: A single static sealing element on the bore. Usually packing or tubing, that is used to prevent injectable sealant from extruding outside the enclosure when using a void fill seal.

Single Seal with Injection Behind: A single static sealing element on the bore, with an injection groove behind it. The static sealing element is usually rope packing, and then injectable sealant is pumped behind the rope packing, under pressure, to compress the packing against the pipe.

Double bore seal: An inner static seal and an outer injectable sealant groove. The inner seal prevents the injectable sealant from extruding inside the enclosures cavity, while the injectable sealant is the primary sealing element. This style of bore seal requires a peening groove on the outside of the bore to prevent sealant extrusion outside the enclosure.

Triple Bore Seal: An inner and outer static sealing element are used to prevent injectable sealant, which is pumped into the middle groove, from extruding in and out of the enclosure.

Cap Nut: A custom nut that is designed to thread onto a stud, and is used to inject sealant into the space between the nut / bolt threads and the bolt hole. Commonly used in leaking flanges or valve bonnets. These are similar to injection rings, but are used when the exposed thread length on the stud is not long enough to allow for a cap nut and the original nut.

Clamp: Slang used to describe a leak repair enclosure

Crunch Teeth:

Machined serrations on the bore of the enclosure, designed to mechanically bite into the pipe surface.

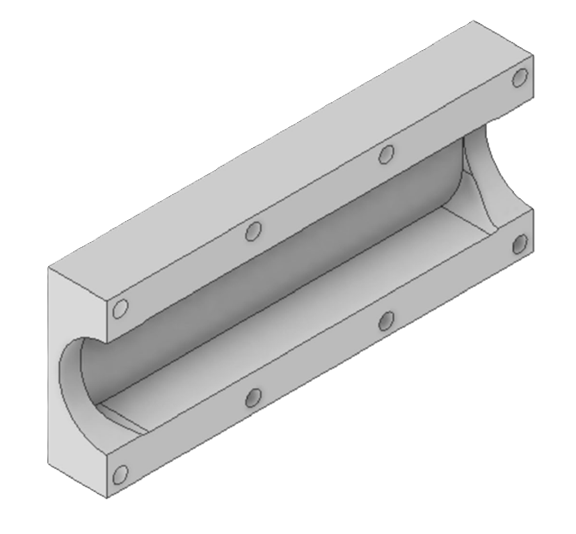

Enclosure: A pressurized housing or clamp that surrounds a pipe or component to contain a leak or provide a sealing path.

High Pressure Packing Gland:

A custom tool that is used to prevent a drill bit from blowing back, towards a technician, when drilling into high pressure equipment.

Hydraulicing: Movement of the enclosure due to unequal pressure areas at the bores.

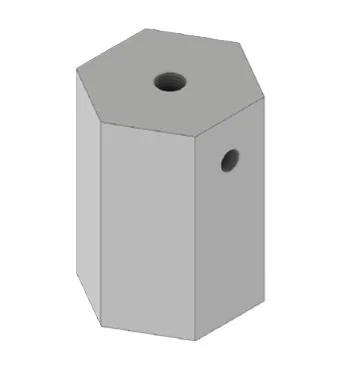

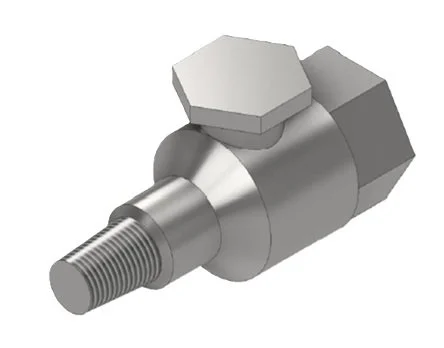

Injection Valve / Injector:

A specialized valve that is designed to inject sealant into an enclosure.

Injection Groove: A recessed groove machined into the clamp bore or face to allow for distribution of sealant.

Injection Gun:

A specialized tool, which used a piston to force sealant under pressure, through a hose, and through and injection valve, into an enclosure.

Injection Port: A threaded hole where an injection valve / injector is installed.

Injection Ring:

A specialized piece of hardware that is placed under a nut / bolt, and is used to inject sealant into the space between the nut / bolt threads and the bolt hole. Commonly used in leaking flanges or valve bonnets.

Packing: A dense material (often graphite or PTFE) used to provide static sealing.

Perimeter Seal: A sealing method where sealant grooves are machined around the perimeter edges of an enclosure to seal off all leak paths.

Plate Box:

An enclosure that is machined from a piece(s) of plate, or a billet. Often all of the enclosure features can be machined into the plate without requiring any welding. Often used on piping less than 12 NPS.

Pipe Box / Fabricated Enclosure:

An enclosure style that is made by welding multiple pieces of materials together. Often used on enclosures larger than 12 NPS.

Secondary Seal: An additional sealing element, often placed after the main seal or in a redundant groove. Used in high-pressure applications.

Strongback(s): An external support designed to keep an enclosure from moving, or pieces of pressure equipment from separating due to a defect

Tubing: Copper or stainless tubing used to provide a static sealing element.

Void Fill: A sealing method where the entire cavity between the inside of the enclosure and the enclosed piping will be filled with sealant. This seals off all leak paths.

If you found this information useful and want to learn more about advanced leak repair methods, don’t forget to subscribe to our channel or join our mailing list. We share new insights and tutorials regularly—stay ahead of your maintenance challenges by staying informed.