Valve Stem Leaks – Online Repair Options (Part 1)

Welcome to the Leak Repair Blog, where we bring engineering insight to the world of industrial leak repair. Today we’re diving into a common and often frustrating issue: valve stuffing box leaks.

Before we begin, please note that this information is for educational purposes only. Always consult your site's Integrity Department or a qualified consultant before attempting any repairs on a leaking valve.

Valve Stuffing Box Leaks are quite common, and there are a few ways to fix them. In this video we'll discuss some of the causes and ways to repair Valve Stuffing Box Leaks.

What Is a Stuffing Box Leak?

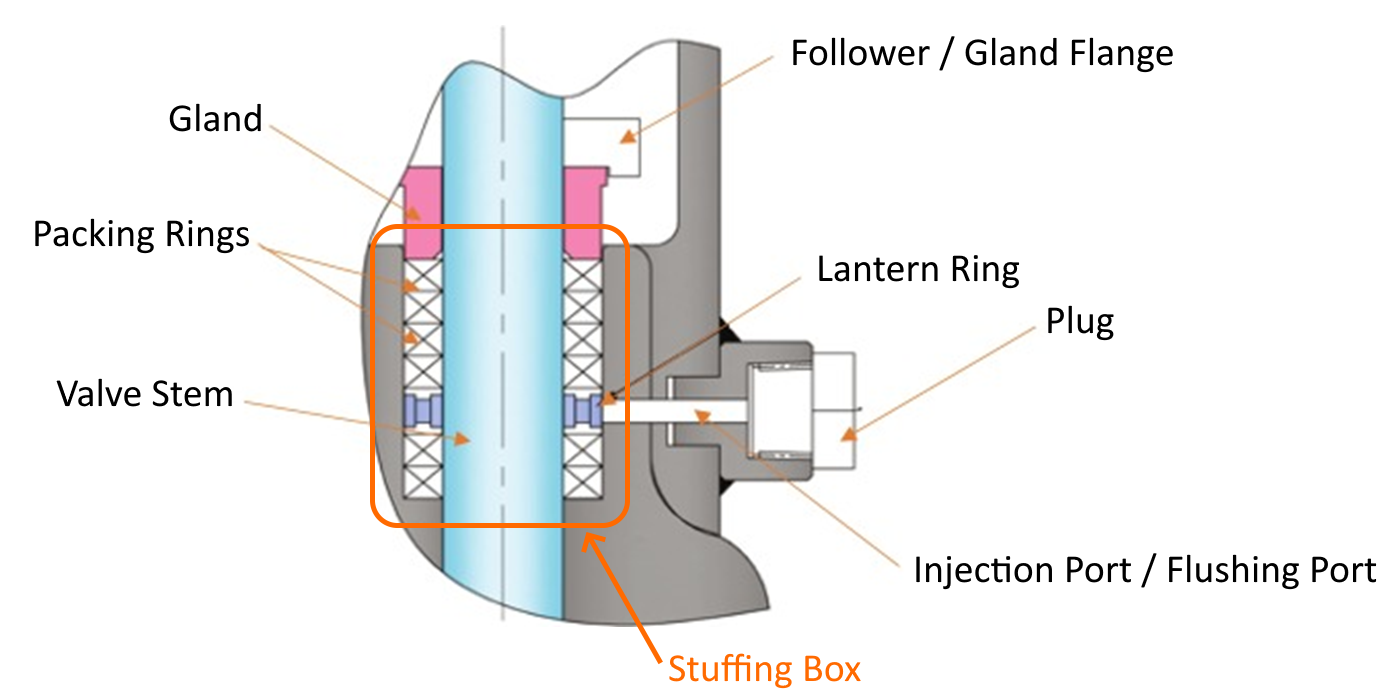

Leaks at the valve stem usually originate from the stuffing box—the part of the valve that contains sealing material, typically rope packing, to prevent leaks along the valve stem.

These types of leaks are common in industrial systems and can arise for several reasons, including:

Worn-out packing

Corroded valve stem

Damaged or failed follower bolts

Over-pressurization

Incorrect packing material

Improper packing installation

Online Repair Methods: No Shutdown Required

All of the repair strategies discussed in this article are considered online repair options. That means they can be performed without taking the valve offline or depressurizing the system. This approach is especially valuable in critical operations where shutting down equipment would be costly, time-consuming, or unsafe.

Important Note: While these methods allow for repair under pressure, they should only be carried out under proper safety protocols and with the guidance of your site's Integrity Department or a qualified consultant.

Step 1: Assess Valve Integrity

Before proceeding with any repairs, it's critical to assess the integrity of both the valve and the follower studs. These studs tighten the packing around the valve stem, creating the seal.

What to Look For:

Cracks or pinholes in the valve body

Cracks in the valve stem

Corrosion or significant rust on follower studs/nuts

Mechanical damage that may compromise safety

If any of these issues are present, do not proceed until the valve has been evaluated by a qualified professional.

Method 1: Tighten the Follower Studs

The simplest repair is to tighten the follower studs, which increases the compressive force on the packing and may stop the leak.

⚠️ Important: Never exceed the manufacturer's torque specifications. Over-tightening can cause stud failure and lead to more serious damage.

This method is low-cost and often manageable by trained facility operators.

Method 2: Stuffing Box Injection

If tightening doesn’t stop the leak, a more advanced method is a stuffing box injection using injectable sealant.

How It Works:

Injectable sealant is compressible, allowing it to fill voids between the packing and the stem. The process typically involves:

Drilling and tapping a hole in the valve body

Installing an injection port

Using a special injection gun to pump in the sealant

Some valves come with pre-installed injection ports, but most require field installation. To safely drill and tap for an injector, the valve body in the stuffing box area should have at least ½ inch of wall thickness. Most injection ports use 1/8" NPT or 3/8" UNC threads.

Safety Consideration: Follower Stud Integrity

Before injecting, confirm that the follower studs are undamaged. Injection increases pressure in the stuffing box, which can place dangerous loads on the follower studs. If the studs are corroded or cracked, they could fail, posing a serious safety hazard.

Method 3: Using a Valve Gag

If follower studs are compromised, you can still perform a safe injection using a valve gag—a custom-engineered device designed to restrain the follower during injection.

What It Does:

Contains internal pressure and injection force

Prevents movement or failure of damaged studs

While effective, valve gags can limit access to other parts of the valve, like bonnet studs, which may be needed for future maintenance. Design and installation must account for these limitations.

Coming Up Next: Enclosure-Based Repair Options

In Part 2, we’ll explore engineered enclosure options for safely containing active valve stem leaks when internal repairs are not feasible.

Stay Connected

If you’d like to learn more about topics like this, please Subscribe to our YouTube Channel or join our mailing list. We’ll send you more great information as it’s released.

Thanks for reading and watching!