Flange Enclosures: A Reliable, Online Solution for Industrial Leak Repair

Flange leaks are among the most frequent and costly issues in industrial plants. Traditionally, repairing a leaking flange meant shutting down the system, depressurizing the line, and disassembling the joint.

Today, however, online leak repair techniques allow technicians to restore mechanical integrity without interrupting plant operations. Among these solutions, flange enclosures have emerged as one of the safest, most versatile, and most effective repair technologies available.

This article explores how flange enclosures work, why they provide significant advantages over traditional clamp-based repairs, and what technical features make them so robust.

What Is an Online Flange Enclosure Repair?

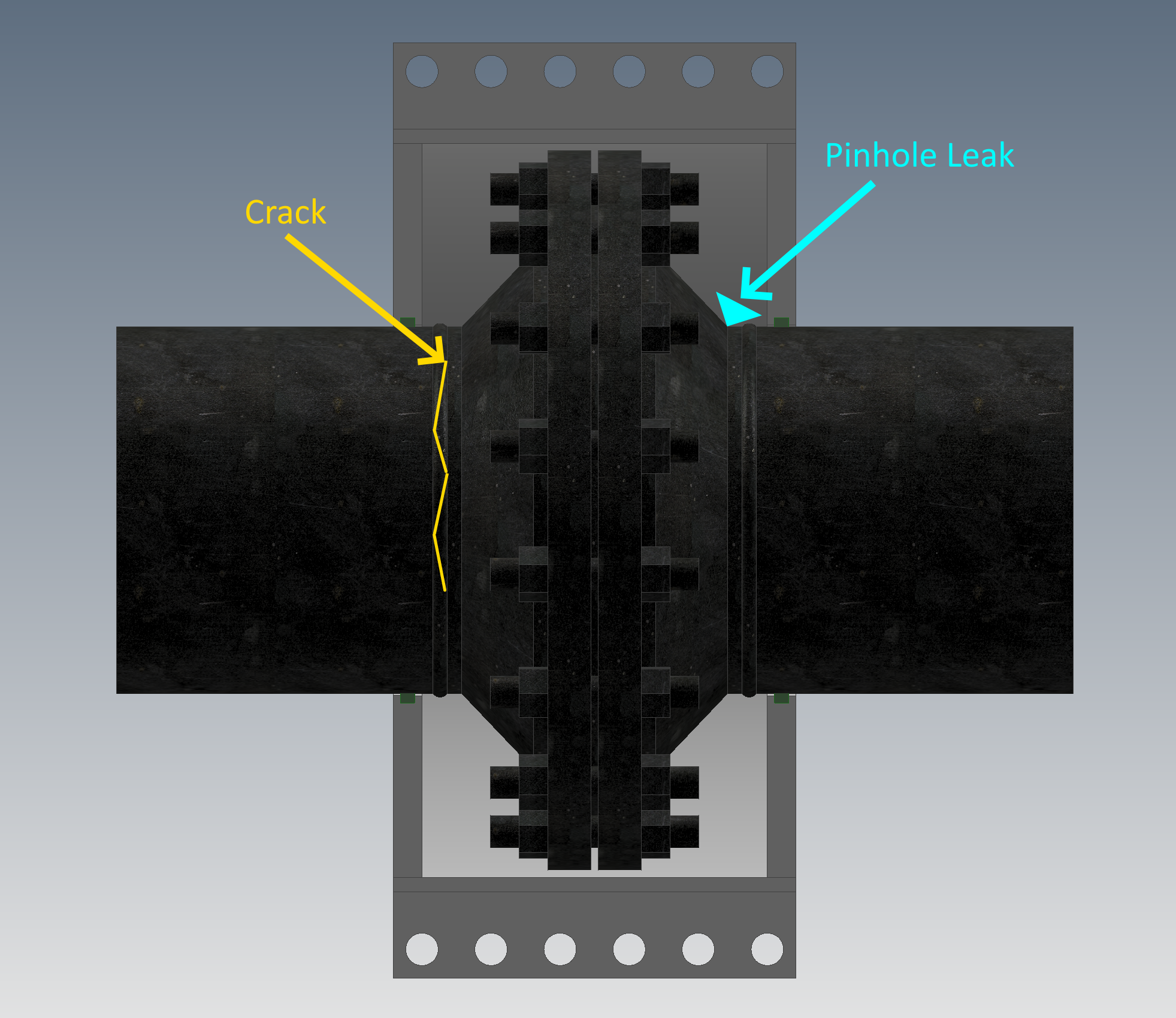

An online repair involves fixing pressurized, operating equipment without the need to shutdown production. A flange enclosure is a specially engineered device that completely surrounds the leaking flange pair, creating an controlled, injectable cavity that becomes the new pressure boundary.

Unlike channel clamps or tongue-and-groove clamps that seal directly on the flange face, a flange enclosure:

Covers the entire flange set

Seals past the welds or threads

Does not rely on flange bolt preload to maintain containment

This makes it an excellent option for gasket leaks, pinholes, cracked welds, or threaded joint failures.

How Flange Enclosures Work

At the heart of every flange enclosure is a multi-layer sealing system designed to create an independent, injectable pressure boundary around the flange. Here’s how the enclosure functions:

1. Enclosure Body With Dual Bores

The enclosure is fabricated as a multi-piece housing that surrounds the flange. The bores are designed to accommodate:

Static sealing elements (packing, tubing or crunch teeth)

Ports for injectable sealant.

Void and perimeter fill pathways.

2. Static Sealing Elements: Packing Tubing or Crush Teeth

Static sealing elements provide the first line of containment.

Packing or tubing is compressed between the enclosure and the pipe surface, forming a tight seal.

Crunch teeth bite into the Pipe OD, creating a metal-to-metal sealing profile.

Both technologies create a sealed boundary that prevents product escape after injection.

3. Injectable Sealant: Void Fill and Perimeter Fill

After the enclosure is torqued in place, technicians pump in a specially formulated sealant. The sealant occupies either:

The entire enclosure void, or

A small perimeter channel, depending on repair strategy

This injected material forms a durable, pressure-retaining barrier.

Why Choose a Flange Enclosure Over a Channel or Tongue Clamp?

No Need for Strongbacking

Channel and tongue-type clamps often require strongbacks to counteract the axial load imposed on the flange when the clamp is pressurized. Strongbacking adds Size, Complexity, Cost and Installation difficulty.

A flange enclosure eliminates this need.

Note that strongbacks may still be required if there is a chance that the pipe will separate from thinning or a crack.

Because the enclosure surrounds both flanges:

Internal pressure acts on the inner faces

External pressure acts on the outer faces

These forces cancel out, meaning no net axial load is transmitted through the flange connection. That is a major engineering advantage.

Simpler, Safer, and More Cost-Effective Installations

Even though a flange enclosure is physically larger than a tongue or channel clamp, field teams can prefer it because the elimination of strongbacks means the installation is simpler.

Ideal for Weld or Thread Failures

Channel clamps and tongue clamps only address gasket leakage. Flange enclosures can address:

Cracked welds

Threaded connection leaks

Pinhole corrosion

General OD degradation

This makes them a versatile option.

When Flange Enclosures Are a Good Choice

Flange enclosures are good leak repair solutions in situations where:

Clamps would require extensive strongbacking

Weld or thread defects are present

A reliable repair is needed

When space allows, flange enclosures often become the preferred solution due to their safety, reliability, and adaptability.

Conclusion

Flange enclosures offer a reliable engineered solution to one of the most persistent problems in industrial operations: flange leaks. By surrounding the entire flange assembly, and often eliminating strongback requirements these enclosures provide a safe, reliable, and cost-effective method for online leak repair.

If you found this information useful and want to learn more about advanced leak repair methods, don’t forget to subscribe to our channel or join our mailing list. We share new insights and tutorials regularly—stay ahead of your maintenance challenges by staying informed.