Accuracy in Action: How 3D Scanning Makes Prefabrication Profitable

In industrial projects, piping replacements and retrofits are often carried out under extreme time and cost pressures. Plant shutdowns, vessel outages, and offshore interventions leave little room for error. Prefabrication—building pipe spools in controlled shop conditions before installation—has long been a strategy to save time and improve quality. Yet, prefabrication depends on one critical factor: Accuracy of Measurements.

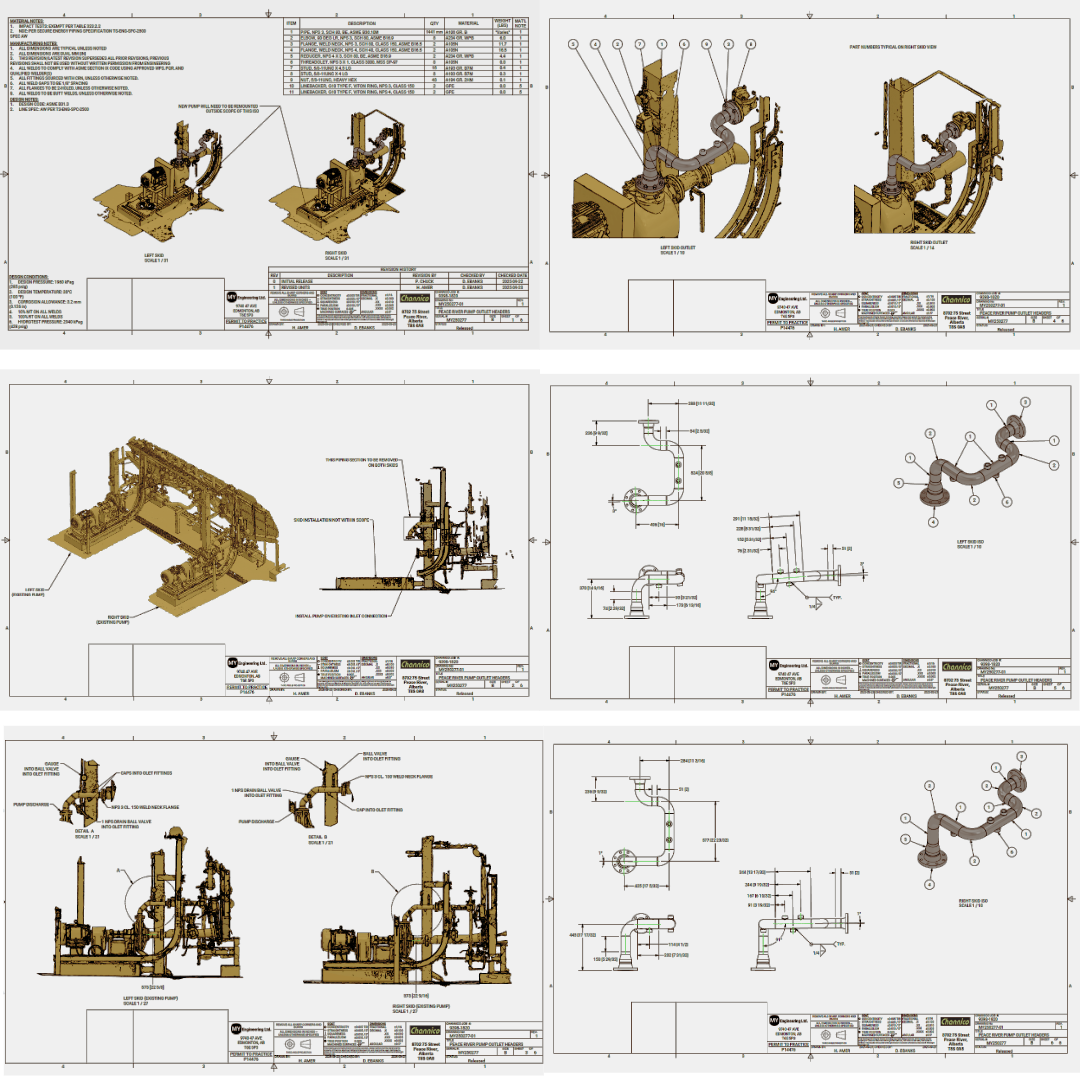

Historically, small errors in manual surveys have led to misaligned spools, emergency field welding, and costly rework. This is where 3D scanning has changed the equation. By capturing the exact as-built environment in millimeter detail, scanning makes prefabrication not only viable but dependable—delivering right-first-time installations.

Why Prefabrication Fails Without Accurate Data

Prefabricated piping offers huge advantages—better weld quality, safer working conditions, and faster installation—but only if the spools fit perfectly. Traditional methods rely on manual measurement with tapes, plumb bobs, and selective 2D drawings.

In congested areas, these approaches are prone to:

Cumulative measurement errors that cause spools to arrive a few millimeters short or long.

Missed obstructions such as cable trays, brackets, or nearby pipework.

Inaccurate tie-in points that require field adjustments or last-minute redesign.

Each of these risks translates into lost time, unplanned hot work, and project uncertainty.

How 3D Scanning Enables Shop-Built Spools

3D scanning eliminates these uncertainties by digitizing the exact geometry of piping systems and surrounding structures. With long-range laser scanners or handheld metrology tools, millions of data points are captured to form a highly accurate point cloud.

From this digital model, engineers can:

Locate tie-in points precisely, ensuring spool dimensions are correct to within millimeters.

Perform clash detection virtually, spotting obstructions before fabrication begins.

Generate accurate isometric drawings and spool sheets that can be trusted by fabrication shops.

Plan installation sequencing with full awareness of surrounding equipment and access routes.

This workflow gives fabricators the confidence that when a spool leaves the shop floor, it will fit correctly the first time in the field.

Benefits for Contractors and Owners

1. Faster Installations

Prefabricated spools can be lifted and bolted into place with minimal adjustment, compressing outage durations and saving significant schedule time.

2. Higher Quality

Shop fabrication allows for controlled welding conditions, better NDE access, and more consistent workmanship compared to field welding in confined or hazardous spaces.

3. Safer Worksites

By minimizing hot work and welding in the field, worker exposure to confined spaces, heights, or hazardous environments is reduced.

4. Lower Total Cost

Even though scanning adds an upfront step, the downstream savings from avoiding rework, reducing site hours, and shortening downtime far outweigh the initial investment.

Conclusion

Prefabrication is only as good as the data it’s built on. With 3D scanning, industrial contractors can replace uncertainty with confidence—delivering spools that fit right the first time, every time. For plant owners, this means safer projects, predictable schedules, and reduced overall cost. In an industry where downtime equals lost revenue, the ability to prefabricate with certainty is not just an advantage—it’s a competitive necessity.