Near or FAR. BIG or small. Trackscan-Sharp is a one-stop solution.

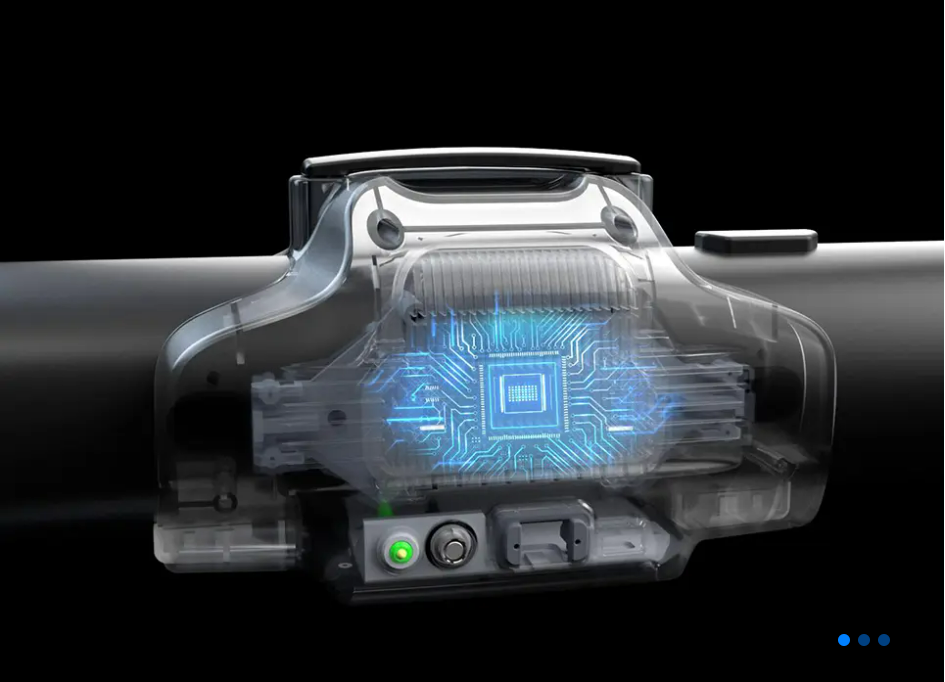

What do you get when you put a 25 megapixel industrial camera into a handheld scanner and combine it with a dynamic optical tracking system, and then throw in a portable CMM probe?

Well, the answer is pretty complex - and that’s a good thing!

The Scantech Trackscan-Sharp Optical 3D Measurement System is so diverse it will deliver metrology grade data with single-point repeatability of up to 0.025, and, thanks to its large tracking volume, which has increased by around 200% from the previous model, users can measure huge parts without compromising precision.

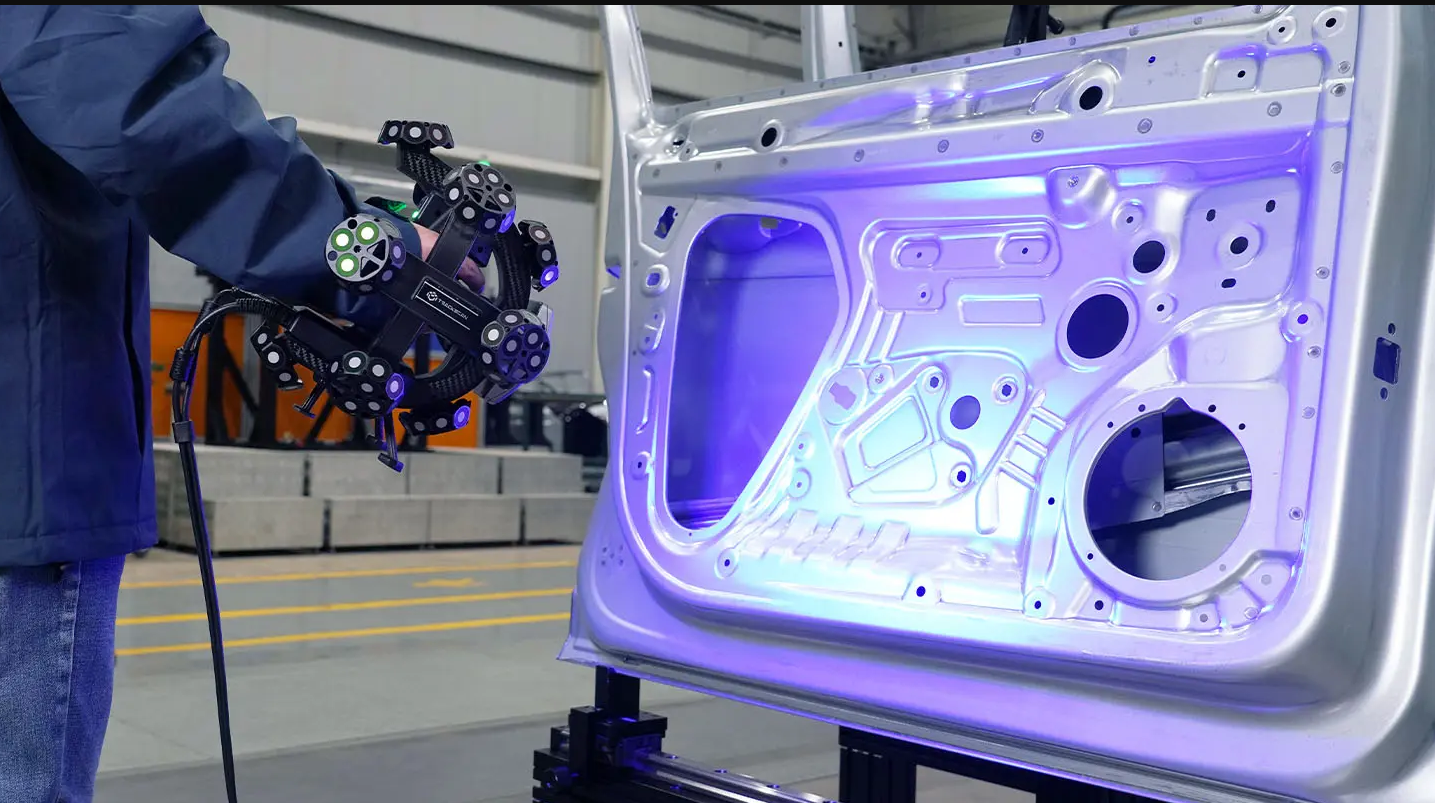

AND, the system has the ability to capture up to 49 cubic meters of data at up to 6 meters away. Basically, this means that with one tracking system set up, you can scan a complete car and then with the Trackscan attachments, capture all the fine details of every aspect of the vehicle, in record time, and with out the hassle of setting up reference markers.

The TrackScan-Sharp enables one-stop scanning of large-scale parts. There is no need for users to move the tracker frequently when measuring large parts, which ensures efficient, smooth, and precise measurements. It supports wired and wireless data transfer to cater to different industrial uses, making scanning even easier. All of these features result in:

Strong Adaptability

Remarkable Accuracy

Large-Volume Measurement

Target-Free Scanning

Metrology-Grade Precision

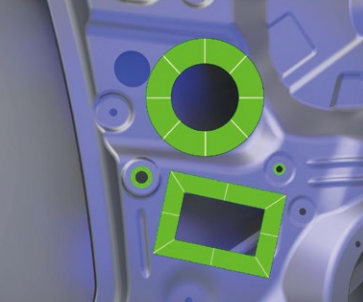

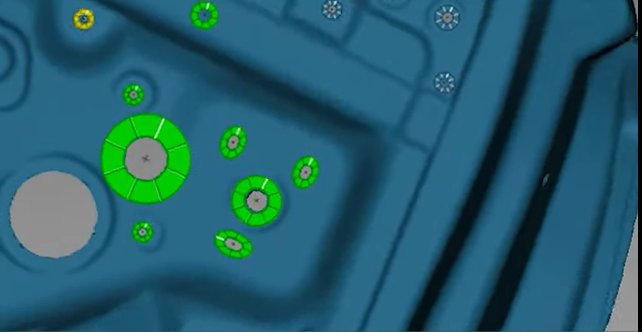

It can also work with an auxiliary light module to inspect holes and slots. Users can inspect closed features precisely, especially threaded holes.

Good measurements are ensured by delivering accurate and repeatable measurement results such as positions and diameters.

Made of carbon fiber, the T-Probe is lightweight, weighting only 450 g. Its portability and ergonomic handle make it easy to gather precise data without being affected by operator fatigue. When paired with T-viewer or third-party software, it can conduct real-time optical probing. The T-Probe attachment offers flexibility with different probe sizes.

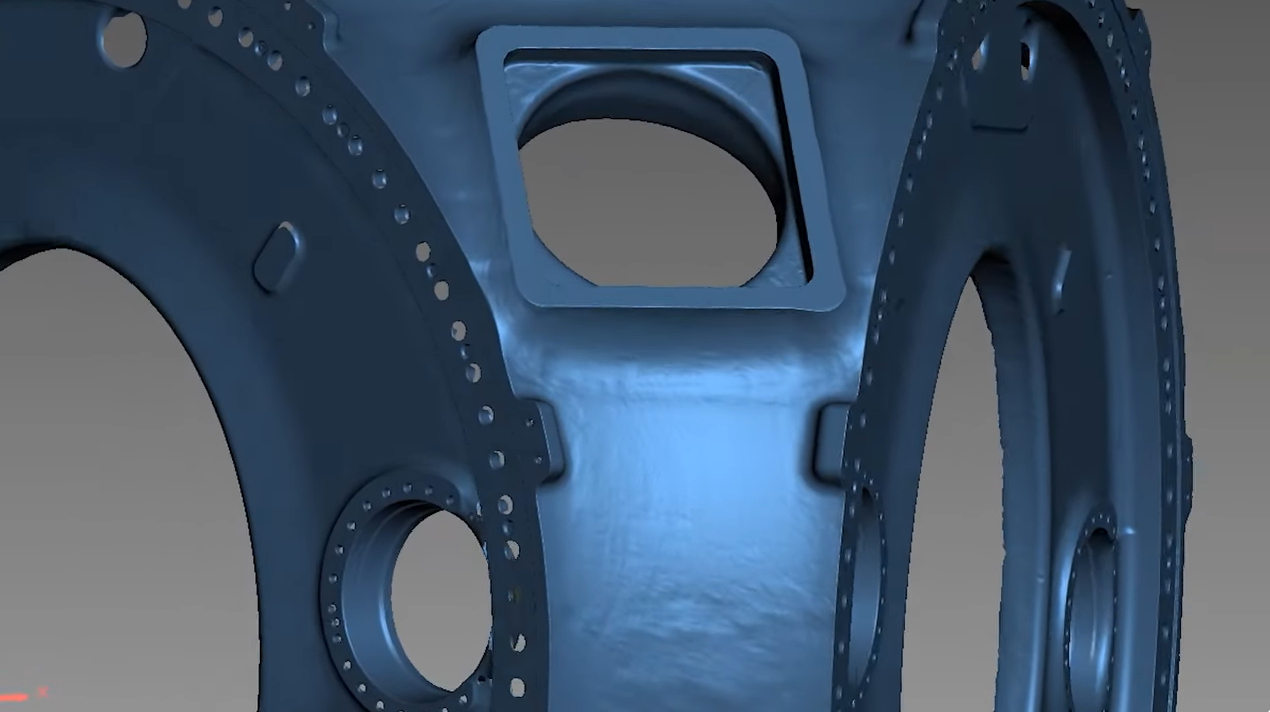

Its highly-adaptive data acquisition algorithm ensures that the Trackscan-Sharp system can easily obtain the 3D data of objects with different surfaces and materials such as reflective, dark, and colorful, making this 3D measurement system excellent for data collection in many industries such as:

Machining

Automotive

Oil and Gas

Aerospace

Mechanical Engineering

Are you curious about how this system can help increase your efficiency? Contact us for a consultation or a demonstration. We’re more than happy to show off this product!