The Power to Maximize Plant Turnaround in YOUR Hands - Part 1

4 Unique Ways Handheld 3D Scan Equipment is Streamlining Processes, Decreasing Costs & Increasing Productivity During Plant Shutdown Operations. Part 1 of a 3 part series.

PLANT TURNAROUNDS. SO MUCH TO DO, SO LITTLE TIME. You already know that proper planning, efficient execution, and effective management is essential to minimize downtime. How do you decide what to prioritize while doing all that’s necessary to ensure continued reliability, efficiency, and safety of the facility? One way to minimize operation disruption during upgrade activities is to arm your team with the power to gather high quality data – quickly and reliably. While precision and accuracy ensures that maintenance tasks are performed correctly (effectively reducing the risk of of future accidents and injuries), metrology grade 3D scan data can reduce time and energy $pent on correcting errors due to communication issues or bad data - which helps keep your shutdown costs within budget.

WHAT IS ‘METROLOGY GRADE’ AND WHY IS THIS IMPORTANT FOR MAINTENANCE? Metrology-grade data ensures precise measurement and inspection of plant equipment and infrastructure. Sub millimeter accuracy is crucial for identifying issues such as corrosion, wear, or misalignment with high confidence. By detecting problems early, maintenance teams can address them promptly, preventing potential failures and minimizing downtime during your plant shutdown.

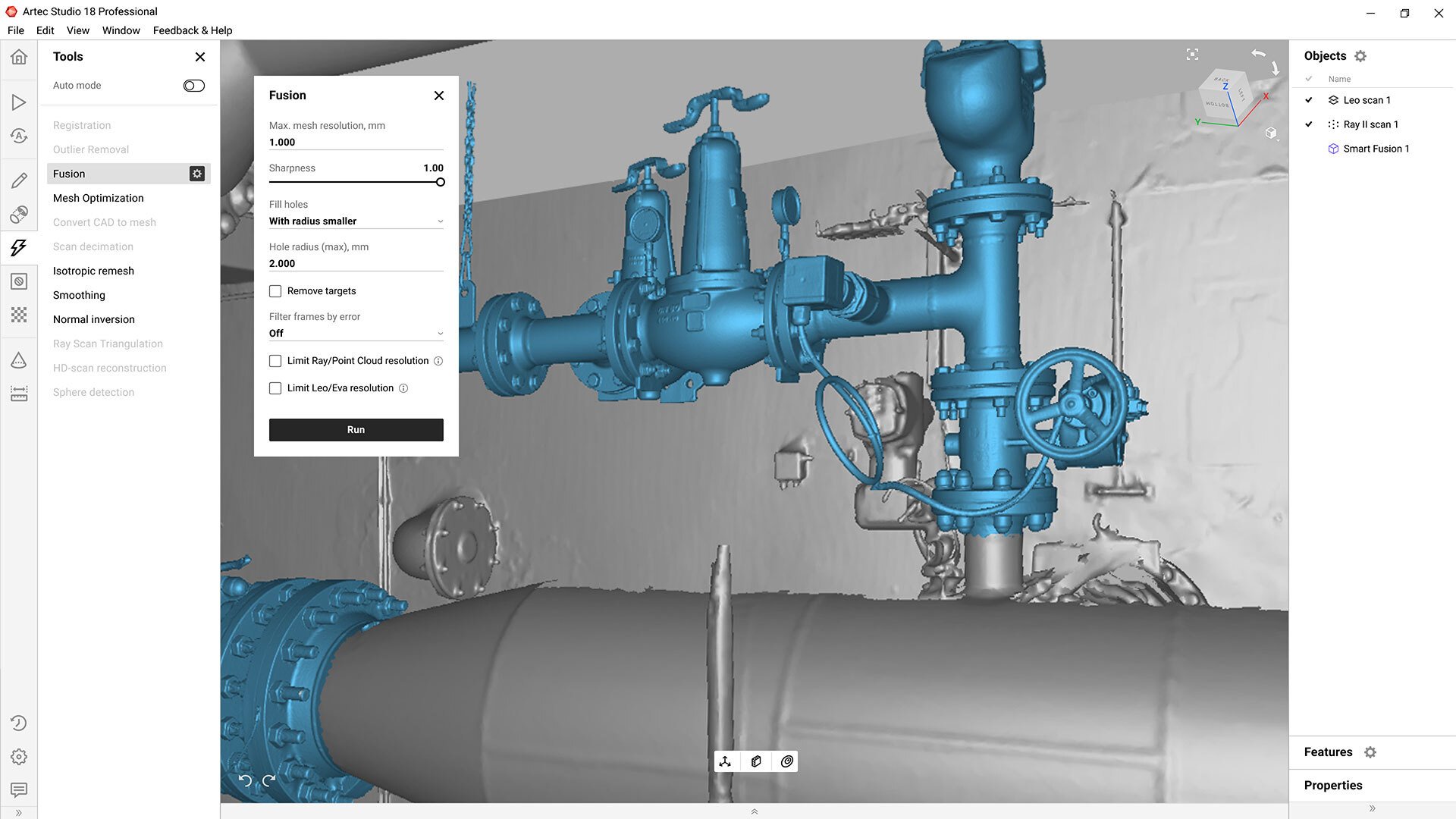

WHAT TYPES OF OPERATIONS CAN A HANDHELD 3D SCANNER BE USED FOR? Metrology-grade data allows for a comprehensive assessment of equipment condition. Detailed 3D models and measurements enable maintenance teams to analyze the integrity of critical components, identify areas of concern, and prioritize maintenance tasks effectively. This ensures that resources are allocated to address the most pressing issues, optimizing your turnaround process.

HERE ARE 4 CRITICAL OPERATIONS WHERE A HANDHELD 3D SCANNER WILL HELP OPTIMIZE EFFICIENCY:

1. Inspecting Flange Faces: Quickly identify and assess damage to flange faces, ensuring seals are perfect - to prevent leaks and potential failures.

2. Measuring Pipe Spool Replacements: Ensure accurate measurements of existing pipes for swift and seamless replacement - minimizing downtime.

3. Quantifying Damage: Use scanners to detect and measure pitting, corrosion, and other damages in equipment - allowing for precise maintenance and repair.

4. Rapid Reverse Engineering: Address supply chain delays by reverse engineering essential on-site components - ensuring continuous operation without long waits for parts.

CAN MY TEAM TRUST A HANDHELD 3D SCANNER DURING OUR PLANT TURNAROUND?

Our professional 3D scanners are built to withstand harsh industrial environments and repeated use. They are often constructed from durable materials such as aluminum or carbon fiber and are designed to maintain accuracy and performance over extended periods of operation.

WHAT ARE MY OPTIONS FOR A HANDHELD 3D SCANNER? High powered, metrology grade 3D scanning technology is now available in sleek, sophisticated, handheld equipment engineered for demanding measurement and inspection tasks – excellent for industries such as oil and gas, petrochemicals, and power generation.

WE SPECIALIZE IN PREMIUM PRODUCTS AND SERVICES. We stand behind our products and we support our clients. We are experienced in the field, and we know what works best to get the results you need.

DON’T PROLONG DOWNTIME WHEN YOU DON’T HAVE TO. Keep your turnaround activities on point - embrace the speed and precision of handheld 3D scanning. With a range of options available to suit any size of project, let us show you how 3D scan technology can make your next turnaround smoother, faster, and more cost-effective. Whether you’re looking to purchase equipment, require expert scanning services, or need comprehensive project support, the team at My Engineering Ltd is ready to work with you.