Small Debris, Big Consequences: Why Clean Pipes Are Critical for Accurate 3D Scanning in Leak Repair

In industrial leak repair and retrofit projects, 3D scanning has become the gold standard for capturing precise pipe geometry. Engineers rely on these scans to create accurate models for clamps, enclosures, and replacement components.

But what seems like a seemingly minor oversight — like leaving insulation residue, scale, or dirt on the surface — can lead to significant dimensional inaccuracies. What looks like harmless fuzz to the eye can actually distort scan data by several tenths of a millimeter, which in tight-fit applications can mean the difference between a perfect seal and a costly leak.

The Measurement Risk: Unclean vs. Clean Piping Data

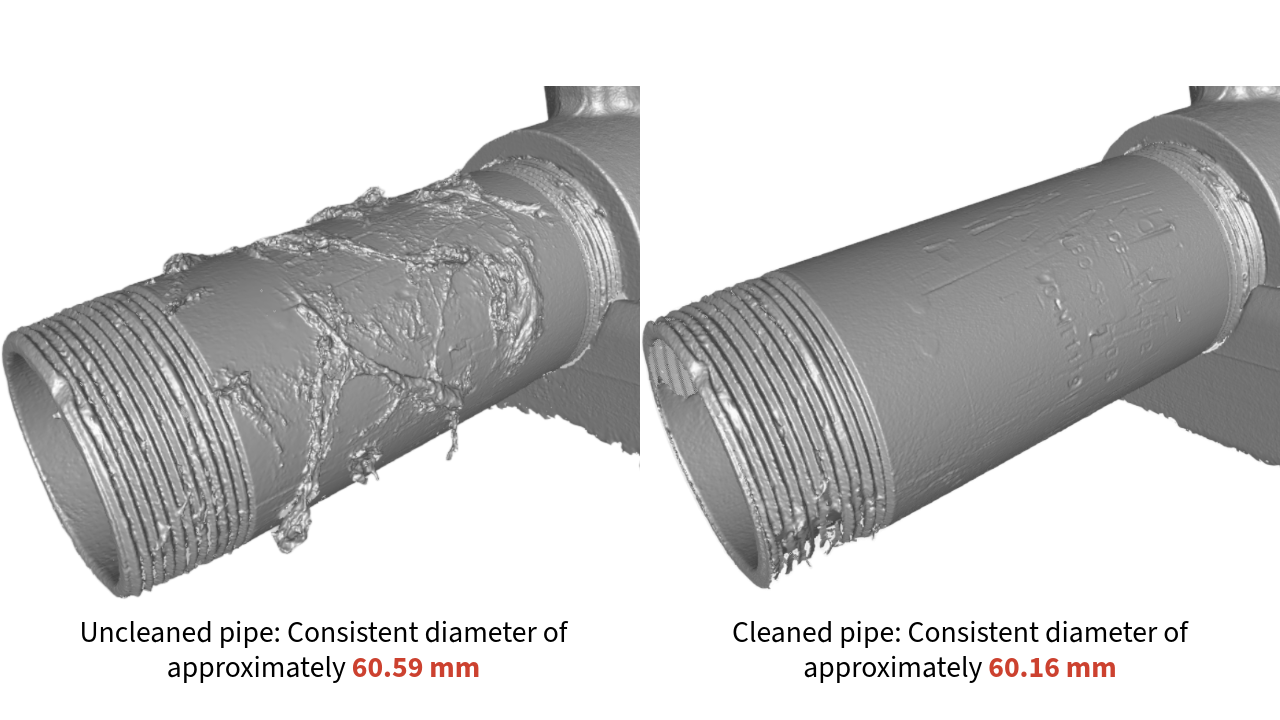

In controlled testing, measurements were taken from two scans of the same pipe — one cleaned to bare metal and the other left with insulation residue and surface debris. The difference in calculated dimensions was immediately evident.

The cleaned pipe produced a consistent diameter of approximately 60.16 mm, while the uncleaned pipe with residual material measured around 60.59 mm.

That 0.43 mm discrepancy, or about 17 thousandths of an inch, may seem minor, but in industrial leak repair and precision fittings, such deviations can have significant consequences. Many engineered enclosures, bore fits, and mechanical seals are designed within ±20 thousandths of an inch of total diametrical clearance. An overestimation of this magnitude can push the fit beyond tolerance, leading to loose assemblies, sealing failures, or mechanical stress once under pressure.

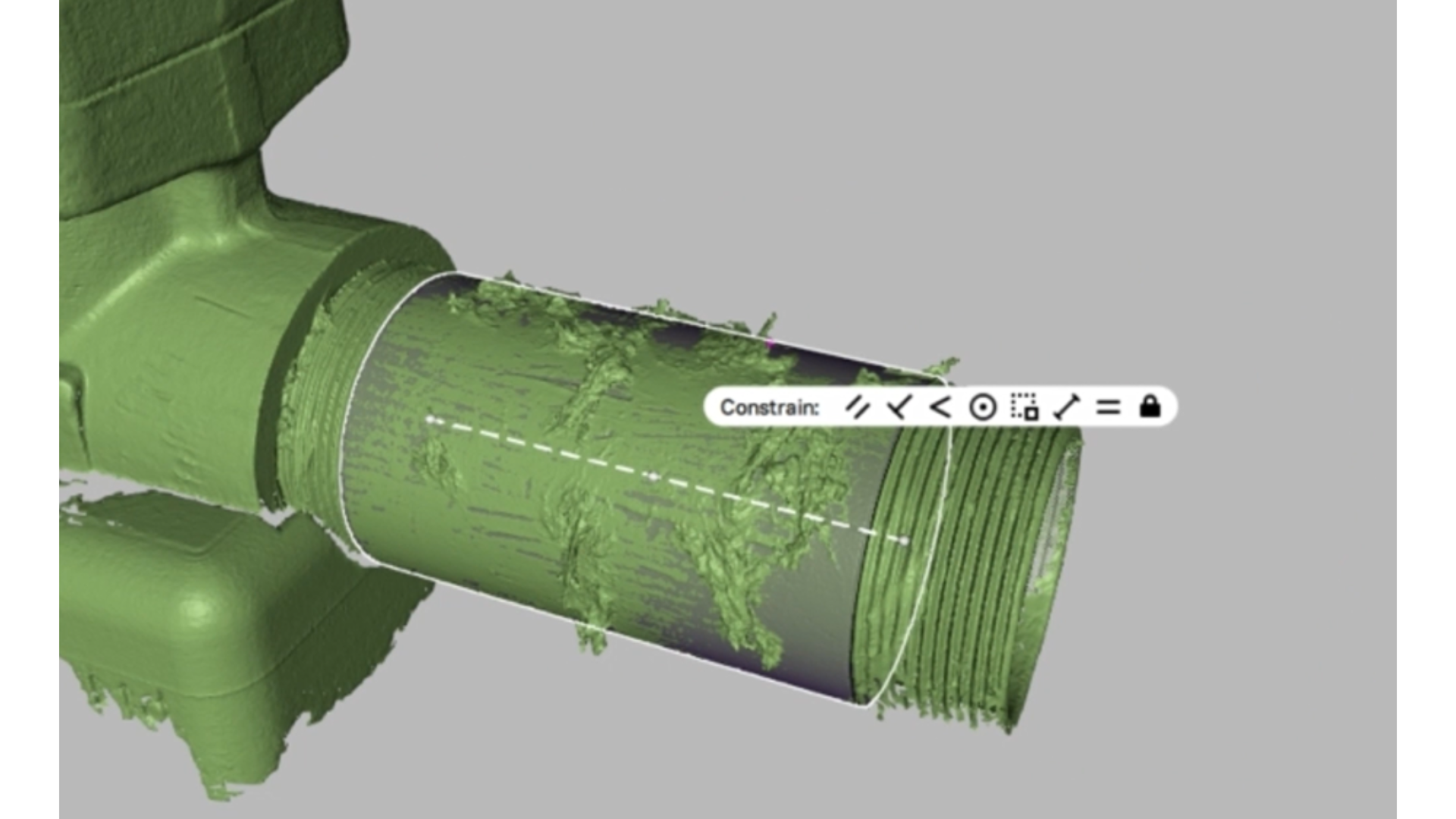

The underlying issue is that scanning systems interpret any visible surface as true geometry. Debris, insulation residue, or corrosion buildup becomes part of the mesh file, artificially inflating the pipe’s perceived outer diameter. When geometric features are extracted — such as cylinders, flanges, or mating faces — those distortions translate directly into the final scanned data.

As a result, components designed from contaminated scan data will not fit properly when manufactured, even if the scan appears visually accurate. This leads to costly redesigns, misaligned hardware, and, in severe cases, field installation failures where clamps or enclosures cannot achieve a proper seal.

The data therefore reinforces a clear engineering principle: 3D scans are only as reliable as the surface condition of the object being measured. Even sub-millimeter surface irregularities can propagate through the modeling process, amplifying tolerances and undermining the precision that 3D scanning is meant to achieve.

The Engineering Theory: How Scanners Interpret Surfaces

Unlike hand tools such as calipers or micrometers, 3D scanners don’t physically contact the surface. Instead, they use Laser or structured light to build a digital representation of the surface geometry.

This introduces a key limitation: The scanner cannot distinguish between the actual material boundary and surface contaminants like fuzz, dust, or residue.

To the scanner, everything it “sees” is part of the geometry. The result is a mesh file that artificially inflates the pipe’s diameter, sometimes unevenly, depending on how the debris is distributed.

When the scan is imported into modeling software, the system performs a “best-fit” cylinder regression — essentially averaging the surface data points to determine the central axis and diameter. If insulation residue remains, the best-fit surface shifts outward slightly, leading to measurable error.

The scan with debris shows localized irregularities, with bumps and clusters of data points where insulation fuzz adhered. These anomalies increased the calculated diameter and created false indications of roundness.

This has cascading consequences in engineering design:

Incorrect mating geometry in clamp or enclosure models.

Poor sealing performance due to excess clearance.

Misalignment when assembling new components around existing piping.

Wasted fabrication time when parts don’t fit as modeled.

Scaling the Problem: Why Larger Pipes Exaggerate the Error

The deviation observed in the previous example, (≈0.43 mm on a 60 mm diameter pipe) might seem minor, but the issue scales proportionally with pipe size and surface contamination.

On a 30-inch industrial pipe, similar surface debris could easily lead to millimeters of error — far exceeding standard engineering tolerances. This can cause flange misfits, bolt alignment issues, or compromised gasket compression during leak repair or enclosure installation.

When performing on-site 3D scanning for large-diameter piping, even slight insulation remnants can create major geometric discrepancies that ripple through the entire design and fabrication process.

3D Scanning vs. Traditional Measurement Tools

It’s worth noting that handheld tools like calipers are less affected by surface debris because the operator can compress insulation and “feel” the true surface.

However, 3D scanners are data-driven, not tactile. They interpret the world purely as visible geometry. This makes them powerful — capable of mapping complex shapes with sub-millimeter precision — but also vulnerable to environmental artifacts.

Best Practices: Preparing for Accurate Industrial Scans

To ensure the highest fidelity scans for leak repair and pipe retrofitting:

Remove all insulation, scale, and dirt — down to bare metal where possible.

Degrease or lightly polish the surface to minimize reflectivity issues.

Inspect mesh quality visually before running any surface fits.

Cross-check scan-based dimensions against manual spot measurements when tolerances are tight.

Conclusion: Clean Data = Confident Engineering

3D scanning is an indispensable tool for industrial maintenance and repair, but data integrity begins at the surface. Even thin insulation residue can distort your measurements and compromise downstream design work.

Whether you’re scanning a 2-inch pipe or a 30-inch header, always clean to bare metal. The few minutes spent preparing the surface will save hours of redesign and refabrication later.

If you found this information useful and want to learn more about advanced leak repair methods, don’t forget to subscribe to our channel or join our mailing list. We share new insights and tutorials regularly—stay ahead of your maintenance challenges by staying informed.