Scan-to-Fit Precision: How 3D Scanning Ensures Zero Rework in Equipment Overhauls

When Microns Matter

In industrial maintenance and rebuild projects, precision is everything. Whether you’re overhauling a pump housing, retrofitting turbine blades, or aligning a gearbox assembly, even minor dimensional errors can cascade into misalignment, vibration, leakage, or early component failure.

Traditional measurement methods — hand tools, 2D drawings, or even CMM sampling — often capture only a fraction of a part’s geometry. That means assumptions fill the gaps. In high-value assets, those assumptions cost time, money, and reliability.

Today, 3D scanning and deviation mapping give engineers a powerful way to achieve “scan-to-fit” precision — ensuring every replacement part, retrofit, or remanufactured component aligns perfectly the first time, eliminating costly rework.

The Challenge: Complexity, Wear, and Fit

Overhauling complex industrial assemblies involves a unique set of challenges:

Non-standard or worn geometries: After years of service, parts no longer match original specs.

Limited or missing CAD data: Many legacy systems have no digital documentation.

Tight tolerances across mating surfaces: Even a minute mismatch can cause misfit or premature wear.

Cumulative error in manual measurements: In large assemblies, small inaccuracies multiply.

In a traditional workflow, engineers would rely on manual measurements or outdated 2D drawings to model replacement components — a process that’s slow, error-prone, and hard to verify until assembly day.

The Solution: Scan-to-Fit Engineering

3D scanning introduces a non-contact, high-accuracy method to capture the true geometry of every surface. Using structured-light or laser scanners, millions of data points are recorded to form a dense 3D mesh — a digital twin of the actual part.

Engineers then use reverse-engineering software such as Geomagic Design X, Artec Studio, or PolyWorks Inspector to extract design features and validate tolerances.

The process typically includes:

High-Resolution Scanning – Parts are scanned to sub-millimeter accuracy.

Mesh Processing & Cleanup – Noise reduction, surface smoothing, and point-cloud alignment.

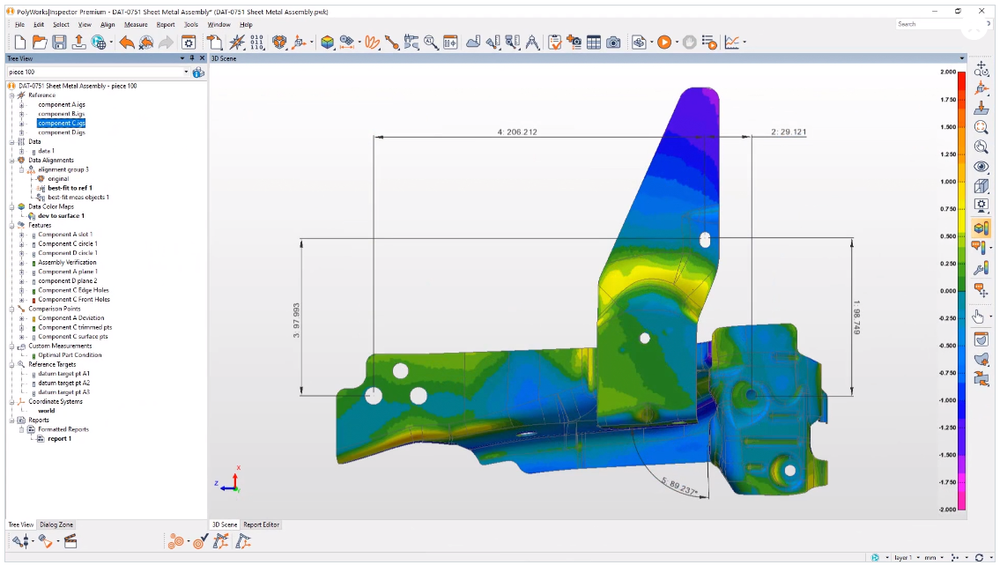

Deviation Mapping – The scanned model is compared against the nominal CAD model to visualize where geometry deviates — color-coded by tolerance bands.

Reverse Modeling or Direct Manufacture – Engineers use the deviation map to modify CAD geometry for a perfect fit before production.

Post-Manufacture Verification – The finished component is re-scanned and compared to the digital master to confirm accuracy.

This closed-loop digital workflow ensures that every stage — from capture to machining — aligns with real-world conditions, achieving “first-fit success.”

Why Deviation Mapping Matters

Deviation mapping is the unsung hero of scan-based engineering. It creates a color-coded heat map showing exactly where a part diverges from its intended geometry.

Red zones indicate excess material or interference.

Blue zones show undersize or wear.

Green zones confirm tolerance compliance.

By visualizing this data, engineers can make informed, data-driven adjustments before any material is cut. For example:

Adjusting a flange to fit a warped housing.

Correcting erosion on an impeller to restore hydraulic balance.

Verifying that a machined surface matches its mating component within ±0.05 mm.

The result? Zero surprises during assembly — and zero rework.

Quantifiable Benefits for OEMs and Maintenance Engineers

The Bottom Line: Precision That Pays

Rework is expensive. Each correction cycle consumes machining hours, inspection time, and lost production. Scan-to-fit precision replaces that guesswork with confidence, giving OEMs and maintenance teams the data they need to get it right the first time.

By pairing 3D scanning accuracy with deviation mapping insight, manufacturers can transform overhauls from reactive to proactive — and maintenance from a cost center into a measurable performance advantage.