Valve Stem Leaks – Online Repair Options (Part 3)

In Parts 1 and 2 of this series, we’ve focused on online leak repair techniques for valve stem leaks. But what happens when your repair requires a pressurized enclosure and you still need the valve to remain operable? That’s where Auxiliary Stem Designs come into play—a smart and effective solution for a complex challenge.

What Is an Auxiliary Stem Design?

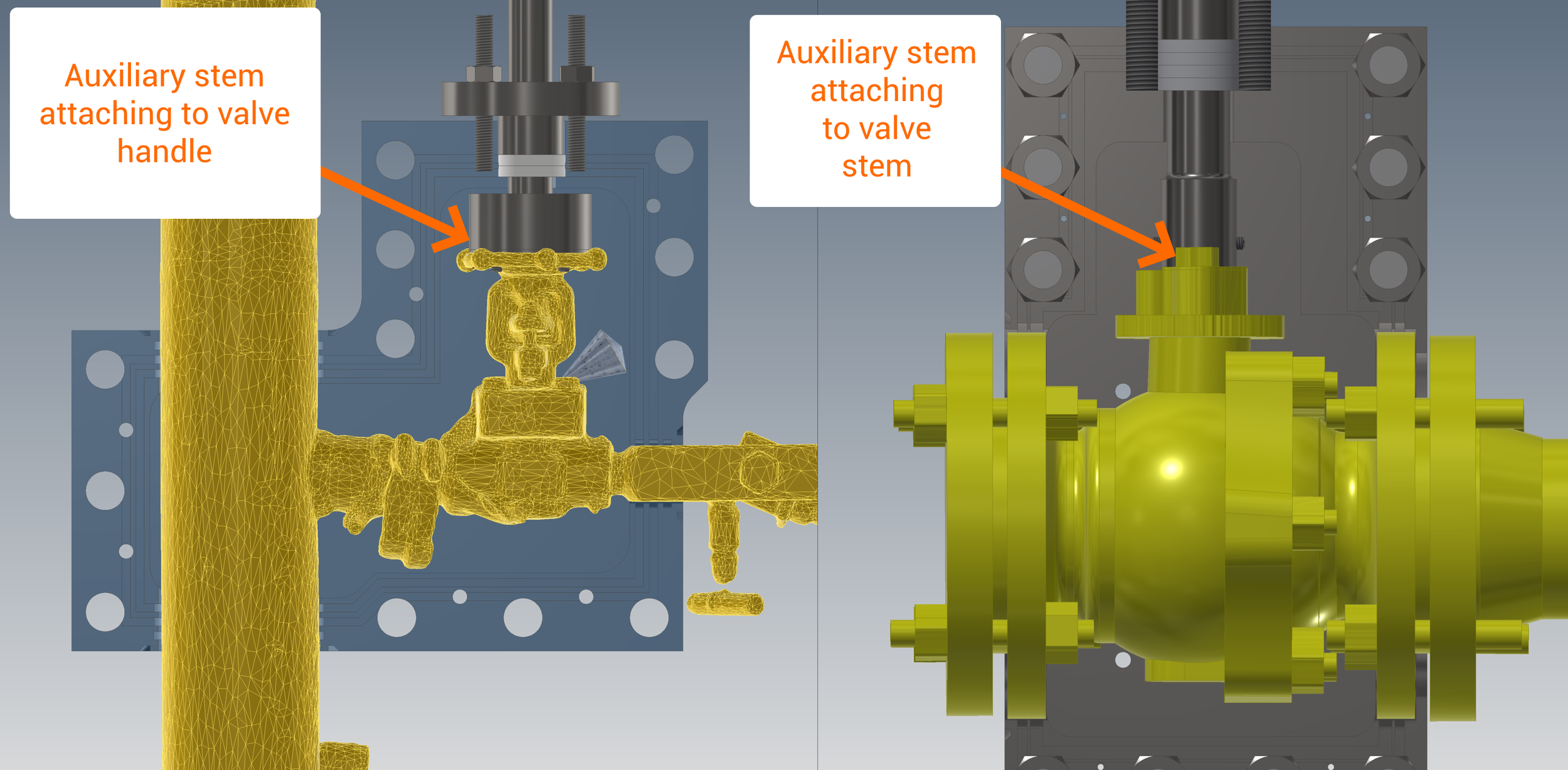

An Auxiliary Stem is a specialized set of engineered components that interface with the existing valve, allowing it to remain functional even when enclosed for leak containment. These designs are tailored to enable operation of the valve through the enclosure, solving a critical problem in many maintenance scenarios.

Let’s break down the typical components of an auxiliary stem design:

Auxiliary Stem

Locking Mechanism / Setscrew

Enclosure and Mounting Hardware

Packing or Die-Cut Grafoil Rings

Follower

Auxiliary Handle

The auxiliary stem itself slides over the original valve stem and is secured—usually via set screws. After the stem is fixed in place, an engineered enclosure is installed over it. This enclosure includes a stuffing box where packing material is compressed around the stem using a follower, forming a reliable seal. Finally, a handle is attached to the auxiliary stem, allowing valve actuation.

Key Design Considerations

There are several best practices and technical nuances that go into designing a reliable auxiliary stem assembly:

Handle Removal: We always recommend removing the existing valve handle to obtain accurate measurements. If the handle can’t be removed, we can design the auxiliary system to connect directly to it—but this often results in a larger and more complex enclosure.

Valve Types: These designs are compatible with both rising stem and rising handle valves. However, rising stem configurations are far more common. In those cases, the interior of the auxiliary stem is drilled out to allow the original stem to rise and fall freely within it.

Seal Choices: Perimeter vs. Void Fill

Because auxiliary stem designs require internal movement, perimeter-style seals are generally preferred. These seals do not interfere with the stem or handle’s motion, making them ideal for enclosures where operability is critical.

In some cases, a void fill is still used, but only with non-curing sealants. A non-curing compound remains malleable and won’t harden over time, preventing any interference with the valve’s operation. Using a curing sealant would effectively bond the moving components together—defeating the very purpose of using an auxiliary stem.

Is It Worth It?

While effective, auxiliary stem designs are:

More complex

More time-consuming to build

More expensive than standard enclosures

Therefore, before you request one, take a moment to evaluate whether continued valve operation is truly necessary during the leak repair. If not, simpler—and more economical—options may suffice.

Final Thoughts

Auxiliary stem designs represent a robust solution for a niche but important problem: performing leak repairs on valves that must remain in service. They exemplify the blend of mechanical engineering, precision design, and real-world practicality that defines everything we do at My Engineering Ltd.

If you found this information useful and want to learn more about advanced leak repair methods, don’t forget to subscribe to our channel or join our mailing list. We share new insights and tutorials regularly—stay ahead of your maintenance challenges by staying informed.