3D Scanners in the Automotive Industry

3D scanners have become a vital part of everyday life in the automotive industry. Designers and engineers can use these scanners from the design and rapid prototyping phases, to the reverse engineering and quality inspection phases.

3D scanners allow automotive manufacturers to measure accurately from 3D data. This can be done for almost any part or component of the vehicle without worrying about the parts size.

3D scanners allow automakers to speed up day-to-day productivity and shorten development lifecycles while facilitating the manufacturing of high-performance vehicles without compromising on quality and safety standards.

3D scanners can be used within the automotive industry for classic car restoration or even new automotive prototyping. Artec 3D's lightning-fast scanners create high-accuracy 3D surface data on every step of design, engineering, prototyping, or manufacturing workflow.

Benefits of using a 3D scanner within the automotive industry

3D scanners such as Artec's LEO, a portable 3D scanner that allows you to capture data from both the interior and exterior of a vehicle, eliminate the need to conduct tedious manual measurements and sketches.

The benefits of using a scanner like LEO include:

9x the speed of a CMM

3D scanners are faster in 3D data capture than contact-based measurement solutions and can capture and store millions of data points per second.

Less than two hours of training required

3D scanners require very little training to be operated. Automotive professionals can start scanning confidently and effectively within two hours of holding a scanner.

3D Scanners are 100% portable

3D scanners are both lightweight and fully portable. The Artec scanners can be quickly taken anywhere they need, whether across the factory floor or a different facility in another city, county, or country.

0 Contact needed

3D scanners are contact-free devices, so engineers and designers scan a full spectrum of surfaces without worrying about any risk of damage or deformation.

10 Microns Accuracy

3D scanners can capture digital data points of auto parts, components, and assemblies with up to 0.01 mm accuracy, making this measurement and data capture far superior to traditional manual methods.

3D Scanner Applications within the Automotive Industry

Inspection and quality control

3D scanners can easily collect and compare 3D scan data to CAD models to help determine the accuracy of the manufactured parts compared to the part designs.

Digital Archive

After scanning all the parts, designers and engineers can digitize all existing components and tools to have a fully digital 3D archive that can be further utilized in CAD/CAM/CAE applications.

3D scanners can help designers replicate and re-create hard-to-find auto parts quickly and easily.

Reverse engineering

3D scanners can quickly capture auto parts that lack documentation in a high-quality 3D image. 3D scanners can also capture technical drawings or parts modified from their original design. Once captured by the 3D scanner, the images can be generated as accurate CAD models for further analysis and development.

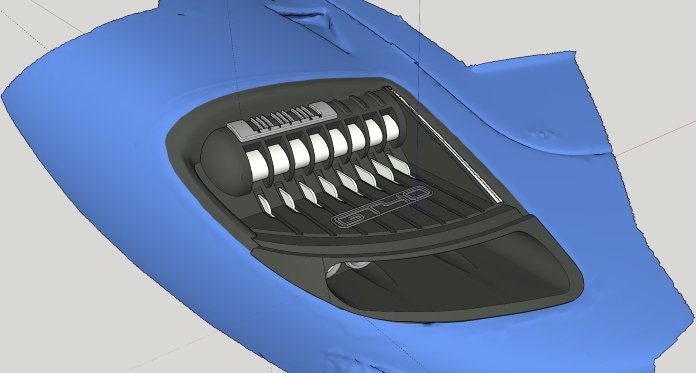

Rapid prototyping

3D scanners allow designers and automotive professionals to rapidly create accurate, high-resolution 3D models of any auto part, component, or entire vehicles, to be used as reference models for new prototypes.

Automotive professionals that are interested in making use of 3D scanners within their business can contact us. Our staff will assist you in finding your business needs.

*Original article and content provided by https://www.artec3d.com/